Check Spiral Wound Gasket Material Suppliers

View Non Asbestos, PTFE Gasket Specification and Temperature Range

Flange Gasket

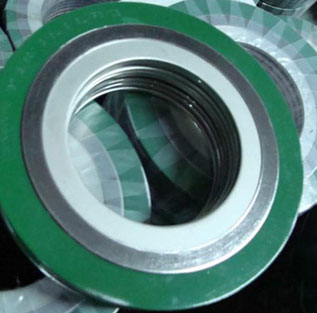

Spiral Wound Gasket

Non Asbestos Gasket

Table of Content

- Specification of Flange Gasket

- Product Range of PTFE Gasket

- Different Non Metallic Flat Gaskets Types

- RTJ Flange Ring Gasket Dimension

- Flat Metal Jacketed Gaskets Size Chart

- 150# Full Face Gasket Tolerance Chart

- Exhaust Pipe Flange Gasket weight chart

- Materials of Spiral Wound Gasket

- Metallic Ring Joint Gaskets Hs Code

- Price List of Flange Rubber Gasket

- Non Asbestos Gasket Temperature Range

Specification of Flange Gasket

- Compressibility : 66% (ASTM-F36)

- Recovery : 16% (ASTM – F36)

- Material : 100% Pure PTFE, produced in an expanded microporous structure

- Temperature : -240 c to + 270 C (for short bursts + 310.C)

- pH range : 0 – 14 pH except molten alkali metals and elemental fluorin

- Pressure : 3000 PSI (210 BAR)

Product Range of PTFE Gasket

| MATERIAL | CONSTRUCTION | RANGE |

|---|---|---|

| Carbon Steel/Stainless Steel with Outer, Inner Ring & Winding | Spiral Wound Gaskets | 1/4”- 48” |

| Compressed Fibre Jointing Material - Neoprene, Epdm, Viton, NBR & Silicon | Non-Asbestos Soft cut Gaskets | 1/4”- 48” |

| Soft Iron, Stainless Steel- 304, 316/316l in R, RX, BX, API 16.20 & API 6A | Ring Joint Gaskets | 1/2”- 24” |

Different Non Metallic Flat Gaskets Types

Triclamp 2"3"4" 6" Buna EPDM Silicone PTFE NBR Gasket for Closed Loop BHO

G10 TYPE E TYPE F 1'' 2'' 3'' Flange Insulation Kit Gasket

FKM FPM Rubber compound Flat rubber o ring gasket

EPDM Flange Rubber Gaskets

ptfe Graphite flat compounds gaskets spiral wound gasket for pipe and flange

Sanitary Hygienic EPDM rubber Gasket Seal

silicone round gasket

Inner and outer ring graphite spiral wound high pressure gasket

PTFE Gaskets

1/8'' thick O-ring Rubber Gasket for Briggs & Stratton 796610 Float Bowl Gasket

API BX Type Ring Joint Gaskets

spiral wound gasket sealing

Stockist of 150# Full Face, RTJ Flange Ring Gaskets, View Exhaust Pipe Flange Gasket Dimensions

RTJ Flange Ring Gasket Dimension

| Size Chart in Inches |

Ring Gaskets | Full Face Gaskets | ||||||||||||

| 125-150 LB | 250-300 LB | 125-150 LB | 250-300 LB | |||||||||||

| OD | ID | OD | ID | OD | ID | Holes | Hole Diameter |

Bolt Circle Diameter |

OD | ID | Holes | Hole Diameter |

Bolt Circle Diameter |

|

| 1/2 | 1 7/8 | 27/32 | 2 1/8 | 27/32 | 3 1/2 | 27/32 | 4 | 5/8 | 2 3/8 | 3 3/4 | 27/32 | 4 | 5/8 | 2 5/8 |

| 3/4 | 2 1/4 | 1 1/16 | 2 5/8 | 1 1/16 | 3 7/8 | 1 1/16 | 4 | 5/8 | 2 3/4 | 4 5/8 | 1 1/16 | 4 | 3/4 | 3 1/4 |

| 1 | 2 5/8 | 1 5/16 | 2 7/8 | 1 5/16 | 4 1/4 | 1 5/16 | 4 | 5/8 | 3 1/8 | 4 7/8 | 1 5/16 | 4 | 3/4 | 3 1/2 |

| 1 1/4 | 3 | 1 21/32 | 3 1/4 | 1 21/32 | 4 5/8 | 1 21/32 | 4 | 5/8 | 3 1/2 | 5 1/4 | 1 21/32 | 4 | 3/4 | 3 7/8 |

| 1 1/2 | 3 3/8 | 1 29/32 | 3 3/4 | 1 29/32 | 5 | 1 29/32 | 4 | 5/8 | 3 7/8 | 6 1/8 | 1 29/32 | 4 | 3/4 | 4 1/2 |

| 2 | 4 1/8 | 2 3/8 | 4 3/8 | 2 3/8 | 6 | 2 3/8 | 4 | 3/4 | 4 3/4 | 6 1/2 | 2 3/8 | 8 | 7/8 | 5 |

| 2 1/2 | 4 7/8 | 2 7/8 | 5 1/8 | 2 7/8 | 7 | 2 7/8 | 4 | 3/4 | 5 1/2 | 7 1/2 | 2 7/8 | 8 | 7/8 | 5 7/8 |

| 3 | 5 3/8 | 3 1/2 | 5 7/8 | 3 1/2 | 7 1/2 | 3 1/2 | 4 | 3/4 | 6 | 8 1/4 | 3 1/2 | 8 | 7/8 | 6 5/8 |

| 3 1/2 | 6 3/8 | 4 | 6 1/2 | 4 | 8 1/2 | 4 | 8 | 3/4 | 7 | 9 | 4 | 8 | 7/8 | 7 1/4 |

| 4 | 6 7/8 | 4 1/2 | 7 1/8 | 4 1/2 | 9 | 4 1/2 | 8 | 3/4 | 7 1/2 | 10 | 4 1/2 | 8 | 7/8 | 7 7/8 |

| 4 1/2 | 7 | 5 | 7 5/8 | 5 | 9 1/4 | 5 | 8 | 3/4 | 7 3/4 | 10 1/2 | 5 | 8 | 7/8 | 8 1/2 |

| 5 | 7 3/4 | 5 9/16 | 8 1/2 | 5 9/16 | 10 | 5 9/16 | 8 | 7/8 | 8 1/2 | 11 | 5 9/16 | 8 | 7/8 | 9 1/4 |

| 6 | 8 3/4 | 6 5/8 | 9 7/8 | 6 5/8 | 11 | 6 5/8 | 8 | 7/8 | 9 1/2 | 12 1/2 | 6 5/8 | 12 | 7/8 | 10 5/8 |

| 7 | 10 | 7 5/8 | 10 7/8 | 7 5/8 | 12 1/2 | 7 5/8 | 8 | 7/8 | 10 3/4 | 14 | 7 5/8 | 12 | 7/8 | 11 7/8 |

| 8 | 11 | 8 5/8 | 12 1/8 | 8 5/8 | 13 1/2 | 8 5/8 | 8 | 7/8 | 11 3/4 | 15 | 8 5/8 | 12 | 1 | 13 |

| 9 | 12 1/2 | 9 5/8 | 12 7/8 | 9 5/8 | 15 | 9 5/8 | 12 | 7/8 | 13 1/4 | 16 1/4 | 9 5/8 | 12 | 1 | 14 |

| 10 | 13 3/8 | 10 3/4 | 14 1/4 | 10 3/4 | 16 | 10 3/4 | 12 | 1 | 14 1/4 | 17 1/2 | 10 3/4 | 16 | 1 1/8 | 15 1/4 |

| 12 | 16 1/8 | 12 3/4 | 16 5/8 | 12 3/4 | 19 | 12 3/4 | 12 | 1 | 17 | 20 1/2 | 12 3/4 | 16 | 1 1/4 | 17 3 4 |

| 14 | 17 3/4 | 14 | 19 1/8 | 14 | 21 | 14 | 12 | 1 1/8 | 18 3/4 | 23 | 14 | 20 | 1 1/4 | 20 1/4 |

| 15′ | 19 | 15 | 22 1/4 | 15 | 16 | 1 1/8 | 20 | |||||||

| 16 | 20 1/4 | 16 | 21 1/4 | 16 | 23 1/2 | 16 | 16 | 1 1/8 | 21 1/4 | 25 1/2 | 16 | 20 | 1 3/8 | 22 1/2 |

| 18 | 21 5/8 | 18 | 23 1/2 | 18 | 25 | 18 | 16 | 1 1/4 | 22 3/4 | 28 | 18 | 24 | 1 3/8 | 24 3/4 |

| 20 | 23 3/8 | 20 | 25 3/4 | 20 | 27 1/2 | 20 | 20 | 1 1/4 | 25 | 30 1/2 | 20 | 24 | 1 3/8 | 27 |

| 22 | 26 | 22 | 27 3/4 | 22 | 29 1/2 | 22 | 20 | 1 1/4 | 27 1/4 | 33 | 22 | 24 | 1 3/8 | 29 1/4 |

| 24 | 28 1/4 | 24 | 30 1/2 | 24 | 32 | 24 | 20 | 1 3/8 | 29 1/2 | 36 | 24 | 24 | 1 5/8 | 32 |

| 26 | 30 1/2 | 26 | 32 7/8 | 26 | 34 3/4 | 26 | 24 | 1 3/8 | 31 3/4 | 38 1/4 | 26 | 28 | 1 5/8 | 34 1/2 |

| 28 | 32 3/4 | 28 | 35 3/8 | 28 | 36 1/2 | 28 | 26 | 1 3/8 | 34 | 40 3/4 | 28 | 28 | 1 5/8 | 37 |

| 30 | 34 3/4 | 30 | 37 1/2 | 30 | 38 3/4 | 30 | 28 | 1 3/8 | 36 | 43 | 30 | 28 | 1 7/8 | 39 1/4 |

| 32 | 38 | 32 | 39 5/8 | 32 | 41 3/4 | 32 | 28 | 1 5/8 | 38 1/2 | 45 1/4 | 32 | 28 | 1 7/8 | 41 1/2 |

| 34 | 39 | 34 | 41 5/8 | 34 | 43 3/4 | 34 | 32 | 1 5/8 | 40 1/2 | 47 1/2 | 34 | 28 | 1 7/8 | 43 1/2 |

| 36 | 41 1/4 | 36 | 44 | 36 | 46 | 36 | 32 | 1 5/8 | 42 3/4 | 50 | 36 | 32 | 2 1/8 | 46 |

| 38 | 43 5/8 | 38 | 46 1/8 | 38 | 48 3/4 | 38 | 36 | 1 5/8 | 45 1/4 | 52 1/4 | 38 | 32 | 2 1/8 | 48 |

| 40′ | 45 5/8 | 40 | 48 3/4 | 40 | 50 3/4 | 40 | 36 | 1 5/8 | 47 1/4 | 54 1/4 | 40 | 36 | 2 1/8 | 50 1/4 |

| 42 | 48 | 42 | 50 3/4 | 42 | 53 | 42 | 36 | 1 5/8 | 49 1/2 | 57 | 42 | 36 | 2 1/8 | 52 3/4 |

| 44 | 50 1/8 | 44 | 53 | 44 | 55 1/4 | 44 | 40 | 1 5/8 | 51 3/4 | 59 1/4 | 44 | 36 | 2 1/8 | 55 |

| 46 | 52 1/8 | 46 | 55 1/4 | 46 | 57 1/4 | 46 | 40 | 1 5/8 | 53 3/4 | 61 1/2 | 46 | 40 | 2 1/8 | 57 1/4 |

| 48 | 54 1/2 | 48 | 58 3/4 | 48 | 59 1/2 | 48 | 44 | 1 5/8 | 56 | 65 | 48 | 40 | 2 1/8 | 60 3/4 |

Class 150 and Class 300 Spiral Gasket Dimensions

| NPS) | Classes 150, 300 |

Class 150 | Class 300 | Class 150 | Class 300 |

|---|---|---|---|---|---|

| Inch | mm | Inside Diameter | Outside Diameter | ||

| 1⁄2 | 31.8 | 19.1 | 19.1 | 47.8 | 54.1 |

| 3⁄4 | 39.6 | 25.4 | 25.4 | 57.2 | 66.8 |

| 1 | 47.8 | 31.8 | 31.8 | 66.8 | 73.2 |

| 1 1⁄4 | 60.5 | 47.8 | 47.8 | 76.2 | 82.6 |

| 1 1⁄2 | 69.9 | 54.1 | 54.1 | 85.9 | 95.3 |

| 2 | 85.9 | 69.9 | 69.9 | 104.9 | 111.3 |

| 2 1⁄2 | 98.6 | 82.6 | 82.6 | 124 | 130.3 |

| 3 | 120.7 | 101.6 | 101.6 | 136.7 | 149.4 |

| 4 | 149.4 | 127 | 127 | 174.8 | 181.1 |

| 5 | 177.8 | 155.7 | 155.7 | 196.9 | 215.9 |

| 6 | 209.6 | 182.6 | 182.6 | 222.3 | 251 |

| 8 | 263.7 | 233.4 | 233.4 | 279.4 | 308.1 |

| 10 | 317.5 | 287.3 | 287.3 | 339.9 | 362 |

| 12 | 374.7 | 339.9 | 339.9 | 409.7 | 422.4 |

| 14 | 406.4 | 371.6 | 371.6 | 450.9 | 485.9 |

| 16 | 463.6 | 422.4 | 422.4 | 514.4 | 539.8 |

| 18 | 527.1 | 474.7 | 474.7 | 549.4 | 596.9 |

| 20 | 577.9 | 525.5 | 525.5 | 606.6 | 654.1 |

| 24 | 685.8 | 628.7 | 628.7 | 717.6 | 774.7 |

Flat Metal Jacketed Gaskets Size Chart

| 150lb Ring Gasket New Standard | ||

| Nominal Pipe Size | Gasket I.D. (Inches) |

Gasket O.D. (Inches) |

| 1/2 | 27/32 | 1 7/8 |

| 3/4 | 1 1/16 | 2 1/4 |

| 1 | 1 5/16 | 2 5/8 |

| 1 1/4 | 1 21/32 | 3 |

| 1 1/2 | 1 29/32 | 3 3/8 |

| 2 | 2 3/8 | 4 1/8 |

| 2 1/2 | 2 7/8 | 4 7/8 |

| 3 | 3 1/2 | 5 3/8 |

| 3 1/2 | 4 | 6 3/8 |

| 4 | 4 1/2 | 6 7/8 |

150# Full Face Gasket Tolerance Chart

| Standard Inner Ring Tolerance | ||||

|---|---|---|---|---|

| Size | I.D. | O.D. | ||

| + | - | + | - | |

| 1" to 3" | + .0312 | - .000 | + .0312 | - .0312 |

| 4" or larger | + .0625 | - .000 | + .0625 | - .0625 |

Check Standard & Thickness of Flat Metal Jacketed and Kammprofile Gasket

Exhaust Pipe Flange Gasket weight chart

| NPS | 150# |

|---|---|

| 1/2 | 1 oz |

| 3/4 | 1-1/2 oz |

| 1 | 2 oz |

| 1 1/4 | 2 oz |

| 1 1/2 | 2-1/2 oz |

| 2 | 3-1/2 oz |

| 2 1/2 | 5-1/2 oz |

| 3 | 6 oz |

| 4 | 8-1/2 oz |

| 5 | 9-1/4 oz |

| 6 | 10 oz |

| 8 | 1 lb |

| 10 | 1-1/4 lb |

| 12 | 1-1/2 lb |

| 14 | 2-1/4 lb |

| 16 | 2-1/2 lb |

| 18 | 2-3/4 lb |

| 20 | 3-1/2 lb |

| 22 | 3-3/4 lb |

| 24 | 3-3/4 lb |

| 30 | 6-1/2 lb |

| 36 | 8-1/2 lb |

| 42 | 10-1/2 lb |

| 48 | 12-1/2 lb |

Materials of Spiral Wound Gasket

| GASKET MATERIALS | BRINELL HARDNESS NUMBER (max) | ROCKWELL HARDNESS NUMBER (max) | |

| Soft iron | 90 | 56 | |

| Low carbon steel | 120 | 68 | |

| 4-6% Chrome 1/2% molybdenum | 130 | 72 | |

| 304 Stainless Steel | 160 | 83 | |

| 316 Stainless Steel | 160 | 83 | |

| 347 Stainless Steel | 160 | 83 |

Metallic Ring Joint Gaskets Hs Code

| Hs Code | Description |

|---|---|

| 6815 | Articles Of Stone Or Of Other Mineral Substances (Including Carbon Fibres, Articles Of Carbon Fibres And Articles Of Pe |

| 68159990 | Other |

| 68151090 | Other |

| 4016 | Other Articles Of Vulcanised Rubber Other Than Hard Rubber |

| 40169390 | Other |

| 40169990 | Other |

| 8484 | Gaskets And Similar Joints Of Metal Sheeting Combined With Other Material Or Of Two Or More Layers Of Metal; Sets Or As |

| 84841090 | Other |

View Price List of Non Metallic Flat, Metallic Ring Joint and Rubber Gasket

Price List of Flange Rubber Gasket

| Gasket Price List | Compressed Naf (cnaf) Gasket Price in INR | Synthetic Fiber Gasket Price in UAE |

|---|---|---|

| Compressed Non Asbestos Joint Sheet Gasket Price | ₹ 77.24/ Kilogram | $3.79 |

| Spiral wound gasket with Flexible Graphite Filler (ASME B16.20) | ₹ 77.24-₹ 1,606.51/ Piece | $3.79 - 78.86 |

| Ring Joint Gasket Octagonal RTJ Gasket | ₹ 100 /Piece | $4.91 |

| ASME B16.21 Oval Soft Iron Flange Ring Joint Gasket RTJ | ₹ 540.66-₹ 772.36/ Piece | $26.54 - 37.91 |

Non Asbestos Gasket Temperature Range

| Material Type | Average Temperature Range in ⁰c |

| Cork | -25 / +135 |

| EPDM Rubber | -40 / +120 |

| EPDM Foam Rubber | -40 / +70 |

| Insertion Rubber | -20 / +70 |

| Natural Rubber | -60 / +220 |

| Styrene Butadiene (SBR) | -50 / + 212 |

| CNAF (Non-asbestos) | -100 / +400 |

| Neoprene Rubber | -30 / + 120 |

| Neoprene Foam Rubber | -40 / + 85 |

| Nitrile Rubber | -20 / + 108 |

| Gasket Paper | -20 / +120 |

| Plastic Shim | -70 / +130 |

| Silicone Rubber | -60 / +300 |

| Silicone Foam Rubber | -60 / +300 |

| Viton Rubber | -25 / +250 |

| Viton Foam Rubber | -25 / +200 |

| Mica (vermiculite) | Excess of +1000 |

| Flexible Graphite | -240 up to +1000 (non-oxidised environment only). |

| PTFE | -73 / + 204 |