PED Certified Bellow Seal Gate Valve Suppliers

PVC Sluice valve Stockist, Check Stainless Steel Gate Valves Specification

Gate Valves

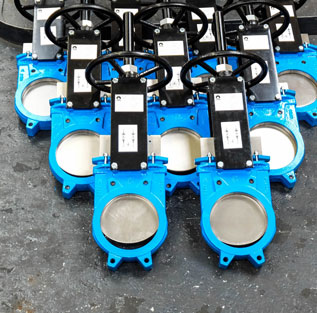

Knife Gate Valves

300PSI API 6A Split Wedge Gate Valve

Table of Content

- Gate Valves Specification Schedule

- What are the different types of Knife Gate Valves Suppliers?

- Dimension Chart of 300PSI API 6a Split Wedge Gate Valve

- Bellow Seal Gate Valves Sizes in MM

- Parallel Slide Gate Valve Weight Chart

- Parallel Slide Gate Valves Temperature Range

- Cast Iron Sluice Gate Valves Advantages & Disdvantages

- Material Chart of Pressure Seal Gate Valves

- Standard Chart of Pressure Seal Bonnet Gate Valves

- Flexible Split Wedge Gate Valve Application

- Solid Flexible Wedge Gate Valve Price Per Piece

- Difference Between Gate Valve And Butterfly Valve

Check Specification Of Parallel Slide and Resilient Seated Gate Valves

Gate Valves Specification Schedule

| Name | Gate Valve |

| Body Material | ASTM, ASME, JIS. Cast Steel / Forged Steel Carbon Steel, 1Cr0.5Mo Steel, 2.5Cr1Mo Steel, Stainless Steel, 9Cr1Mo-V Steel, etc. |

| Fluid | Water, Steam, Gas, Oil, etc. |

| Pressure Class, Size(Standardized) |

Class 150 - 2500: - 600 mm Class 3500: - 400 mm Class 4500: - 300 mm |

| Connection Form | Socket weld, butt weld, flanged* |

| Operation Method | Manual (including the type with a manual reduction gear), electric |

What are the different types of Knife Gate Valves Suppliers?

DIN 3352 F4/F5 Ductile Iron Pn25 Resilient Seated Gate Valves

150lb~1500lb Wcb CF8 CF8m Stainless Steel Flanged Gate Valves

Flange Type Hand Wheel Non-Rising Resilient Gate Valves

7-1/16 Inch 5m API 6A FC Gate Valves

API Carbon Steel Wcb Flanged Rising Stem Gate Valves

Cast and Forged Gate Valves (Z41H)

ANSI/API/ASTM/ASME/Wcb Flanged Gate Valves

Electric Actuator Operated Soft Seated Gate Valves

Cast Steel Flange End Gate Valve

A182 F304 PN100 DN20 Manual RF Flange Gate Valve

Wafer Knife Gate Valve Pn10

Resilient Seated Non-Rising Stem Gate Valve

Bellow Sealed Gate Valve

Cryogenic Gate Valve Class 900, 1500, 2500

Pneumatic Actuated Knife Gate Valve

ASME B16.34 Class 600 LB Pressure Seal Gate Valve

Dimension Chart of 300PSI API 6a Split Wedge Gate Valve

| SERIES 2500/2500-1 | ||||||||

|---|---|---|---|---|---|---|---|---|

| Valve Size | 2" | 2-1/2" | 3" | 4" | 6" | 8" | 10" | 12" |

| A | 8.44 | 11.03 | 11.84 | 13.91 | 17.12 | 20.47 | 24.06 | 27.59 |

| B | 9.36 | 12 | N/A | N/A | N/A | N/A | N/A | N/A |

| End to End (Class 125) | 7 | 7.5 | 8 | 9 | 10.5 | 11.5 | 13 | 14 |

| End to End (Class 250) | N/A | N/A | 11.12 | 12 | 15.88 | 16.5 | 18 | 19.75 |

| Handwheel Dia. | 7 | 8 | 8 | 10 | 12 | 14 | 15.5 | 15.5 |

Bellow Seal Gate Valves Sizes in MM

Size Chart of Gate Valve 150 Class

| Size DN | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 650 | 700 | 750 | 800 | 900 | 1000 | 1050 |

| L-RF | 178 | 191 | 203 | 228 | 254 | 267 | 292 | 330 | 355 | 381 | 406 | 432 | 457 | 508 | 559 | 609 | 609 | 660 | 711 | 812 | 860 |

| **L1-BW | 216 | 241 | 282 | 304 | 381 | 403 | 419 | 457 | 501 | 571 | 609 | 660 | 711 | 812 | 863 | 914 | 914 | 965 | 1016* | 1066* | 1143 |

| H (approx) | 425 | 435 | 535 | 600 | 705 | 800 | 1010 | 1250 | 1385 | 1575 | 1825 | 1950 | 2080 | 2425 | 2750 | 2825 | 3175 | 3473 | 3600 | 4100 | 4500 |

| ØW | 200 | 250 | 250 | 280 | 300 | 350 | 450 | 500 | 350* | 350* | 350* | 350* | 400* | 400* | 450* | 450* | 500* | 500* | 500* | 500* | 500* |

| Wt kg | 22 | 29 | 37 | 56 | 78 | 84 | 138 | 210 | 310 | 450 | 565 | 740 | 927 | 1125 | 1425 | 1550 | 1950 | 2200 | 3050 | 3265 | 4250 |

Gate Valve 300 Class Sizes

| Size DN | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 650 | 700 | 750 |

| L-RF, LI- BW | 216 | 241 | 282 | 305 | 381 | 403 | 419 | 457 | 502 | 762 | 838 | 914 | 990 | 1143 | 1244 | 1346 | 1369 |

| H (approx) | 430 | 475 | 535 | 605 | 715 | 845 | 1075 | 1260 | 1425 | 1585 | 1845 | 1995 | 2175 | 2650 | 2850 | 3050 | 3270 |

| ØW | 200 | 200 | 250 | 300 | 300 | 350 | 450 | 500 | 500 | 350* | 400* | 450* | 450* | 500* | 500* | 500* | 550* |

| Wt (approx) kg | 28 | 40 | 53 | 80 | 125 | 152 | 245 | 360 | 532 | 725 | 950 | 1350 | 1648 | 2350 | 2900 | 3400 | 4100 |

Parallel Slide Gate Valve Weight Chart

Weight of Cast steel gate valves flanged RF ANSI class # 150

| DN | L mm. | H mm. | D mm. | Weight kg. |

|---|---|---|---|---|

| 2" | 178 | 320 | 152 | 23 |

| 3" | 203 | 400 | 190 | 39 |

| 4" | 229 | 470 | 228 | 53 |

| 6" | 267 | 650 | 279 | 84 |

| 8" | 292 | 800 | 342 | 144 |

| 10" | 330 | 1070 | 406 | 219 |

| 12" | 356 | 1200 | 482 | 317 |

| 14" | 381 | 1320 | 533 | 403 |

| 16" | 407 | 1450 | 596 | 457 |

| 18" | 432 | 1300 | 635 | 668 |

| 20" | 457 | 1780 | 698 | 894 |

| 24" | 508 | 2200 | 813 | 1150 |

View Large Inventory and Properties of Cast Iron and Pressure Seal Bonnet Gate Valves

Parallel Slide Gate Valves Temperature Range

| Valve Type | Minimum Temperature |

Maximum Temperature |

||

|---|---|---|---|---|

| oC | oF | oC | oF | |

| Gate | -272 | -455 | 675 | 1250 |

Cast Iron Sluice Gate Valves Advantages & Disdvantages

| Advantages | Disadvantages |

| Available in large sizes | Low pressure limitations |

| Can be used with slurries and viscous liquids | Slow open and close time |

| Used as a shut off valve | Erosion of the seat and disk can occur |

| Easy to maintain and disassemble | Poor throttling characteristics |

| Inexpensive | Difficult to repair |

| Inherently fire-safe (when used with a metal sheet) | Should not be used in sanitary applications |

| Bidirectional |

Check Our Global Sales Network For Slab and AWWA c515 Gate Valve Material

Material Chart of Pressure Seal Gate Valves

| body-bonnet | cast steel A216WCB, GP240GH+N |

|---|---|

| stem | A182 F6 |

| body seat facing | A182 F6 |

| wedge ring facing | A182 F6 |

| stem packing | graphite |

| gasket | graphite |

| painting | high clorinated polyethylene HCPE |

Standard Chart of Stainless Steel Gate Valve Pn16

| Design | ASME B16.34 / API 600 / IBR |

| Temp Rating Chart | ANSI B16.34 |

| Face to Face & End to End Dimensions Chart | ASME B16.10 (upto 36") |

| Flange Ends | ASME 16.47 (above 24") / ASME B16.5 (upto 24") |

| ButtWeld Ends | ASME B16.25 |

| Testing | API 598 / EN 12266 PART 1 (BS 6755 PART 1) |

Flexible Split Wedge Gate Valve Application

- It is used in lube oil, hydrocarbon, air, fuel gas, feedwater, steam, and all most any services.

- It is used in slurry and powder product also such as knife gate valve

- They are suitable to use in high temperature and pressure conditions

- They are used for on-off applications

Solid Flexible Wedge Gate Valve Price Per Piece

| Gate Valve | Price list |

|---|---|

| Electric Knife Gate Valve(API CE approved) 380VAC 220VAC | US$ 100.00-US$ 1,200.00 / Set |

| Ductile Iron Resilient Flanged Gate Valve | US$ 10.00-US$ 100.00 / Piece |

| DIN F4 GGG50 DN100 resilient seated ductile iron valve | US$ 45.00 / Set |

| Forged Solid Brass Full Port Gate Valve | US$ 0.60-US$ 8.00 / Piece |

| API 6A Hydraulic FCL gate valve | US$ 5,000.00-US$ 10,000.00 / Piece |

Difference Between Gate Valve And Butterfly Valve

| Gate valves | Butterfly valves |

| 1. It is known as sluice valves | 1. It as known as flap valves |

2. Body-Bonnet Designs

|

2. Body Designs

|

3. Disc Designs

|

3. Disc Offset Designs

|

| 4. it is use a movable door or gate to open and close the valves. | 4. The category of quarter-turn valves and they consist of a rotating disc to regulate the medium flow. |

| 5. Characteristics: light weight, flat bottom gate seat, integral glue coating, precision casting valves body. |

5. Characteristics: Simple structure, small size, light weight, low material consumption, small installation size, fast switching |

Gate Valves Stocking Distributor Of Following Manufacturers in UAE

Knife Gate Valves Stockist in UAE

Stockholder Of 300psi Api 6a Split Wedge Gate Valve in UAE

Bellow Seal Gate Valves Stockholder in UAE

Supplier Of Bellow Sealed Gate Valves in UAE

Parallel Slide Gate Valves Supplier in UAE

Stock Of Cast Iron Sluice Gate Valves in UAE

Pressure Seal Gate Valves Stock in Dubai

Pressure Seal Bonnet Gate Valves Stocking Distributor in Dubai

Stocking Distributor Of Flexible Split Wedge Gate Valves in Dubai

Solid Flexible Wedge Gate Valve Stock in UAE

Parallel Slide Gate Valve Stockist in Dubai

Stockholder Of Slab Gate Valve Api 6d in Dubai

Split Wedge Disc Gate Valve Stockholder in Dubai

Split Wedge Type Gate Valve Stocking Distributor in UAE

Stocking Distributor Dn150 Flanged Gate Valve in UAE

Stock Of Electric Actuated Knife Gate Valve in UAE

Stockist Of Bolted Bonnet Gate Valve in UAE

Stock Of Forged Steel Gate Valve in Dubai

Stockist Of Parallel Gate Valves in Dubai

Supplier Of Conduit Gate Valve in Dubai

Non-rising Stem Gate Valve Supplier in Dubai

Stock Of Manual Gate Valve in Dubai

Electric Gate Valve Actuator Stock in UAE