Fully Welded Stainless Steel Ball Valve Suppliers

Stockist of Metal Seated, Float and Ball Check Valves

Ball Valves

2 Way Ball Valves

3 Way Ball Valves

Ball Check Valves

Trunnion Mounted Ball Valve

Ball Float Valve

Table of Content

- Ball Valves Specifications

- Types Of 2 Way Ball Valves

- Pneumatic Three Way Ball Valve Standards Chart

- Material Construction of Pneumatic Ball Valve Actuator

- Trunnion Mounted Ball Valve Dimension Chart

- International Standards of Ball Check Valves

- Ball Valve Vs Plug Valve

- Ball Valve Flange End Temperature Range

- Ball Float Valve Price per Piece

- Weight Chart of 3-Piece Trunnion Mounted Ball Valves - API 6D

Ball Valves Specifications

| Size in mm | 6mm to 750mm |

| Types | One Piece, Two Piece, Three Piece, 3 Way, 4 Way |

| Body Material List | CF3, CF3M, CN7M, WCB, CI, CS, SS, AS, A 105, CF8, CF8M, Alloy 20 |

| End Connection | Butt Weld End / Flanged End / Screwed End / Screwed to BSPT / NPT / Socket Weld / Buttweld with extended Nipple |

| Optional | Trunnion Motorised Ball, Motorised Operation or Manual Gearbox/td> |

| Pressure Rating Chart | ASA 150#, 300#, 600#, 800#, 900#, 1500#, 2500# |

| Operation | Lever, Electrical Actuator, Gear, Pneumatic Rotary Actuator |

| Design & Manufacturing Standards | API-6D, BS-5159, BS-5351, ISO 17292 |

| Seat & Seals | Graphite, PTFE, Buna-N, Reinforced PTFE, Graphoil |

Types Of 2 Way Ball Valves

2PC Stainless Steel Floating Ball Valve

Full Port Trunnion Mounted Flanged Ball Valve

Carbon Steel Wcb 3-PC Ball Valve Dn50 Pn16

3 Piece Stainless Steel Sanitary Manual Full Port Ball Valve

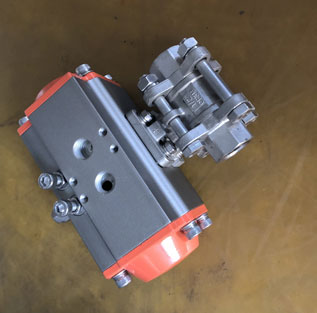

RF Dn15-100 Three Piece Pneumatic Full Package Ball Valve

Stainless Steel 304 2PC Floating Ball Valve Threaded Ends 1000WOG

DN15 - DN100 Pressure PN25 Cw617n or HPB59-3 Brass Ball Valve

Stainless Steel NPT female threaded ball valve

3 pc stainless steel ss316 ball valve dn50

Stainless Steel 304 Female Threaded 1/2 Inch Mini Water Ball Valve

Plastic PVC Ball Valve 1/2 Inch to 6 Inch

Pneumatic Three Way Ball Valve Standards Chart

| Scope | Standard |

| Design* | ISO 17292/ API 6D |

| Socket-weld ends | ASME B16.11 |

| Screwed-end BSPT | ISO 7-1 |

| Screwed-end NPT | ASME B1.20.1 |

| End flange | ASME B16.5 RF/ FF/ RTJ |

| Face-to-face (Flanged) | ASME B16.10 |

| Pressure testing | ISO 5208/ API 598 |

Floating Ball Valve Characteristics

- No lower stem, providing savings during constrution

- Relatively small size , typically from 1/2 – 12″

- Tight sealing ability via the ball on the seat

- Low operating torque

- Downstream sealing only

- It is fixed, it does not float

- ItThe ball is centered by the stem at the top and trunnion at the bottom

- More complex than floating valves

Construction of Ball Valves

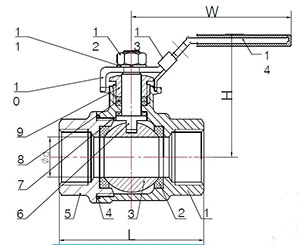

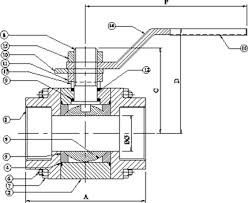

Major parts of the ball valve are the spherical plug, body and seats. They are made in three patterns: venturi, full, and reduced port. The full-port valves has an inside diameter equal to the inside diameter of the pipe. In the venturi and reduced-port Valve, the port is generally one pipe size smaller than the line size.

Material Construction of Pneumatic Ball Valve Actuator

| No. | Part | Material specification Chart | ||

| Single-piece Ball valve | Two-piece Ball valve | Three-piece Ball valve | ||

| 1 | Body/ Connector/ Insert | ASTM A216 Gr. WCB | ASTM A216 Gr. WCB ASTM A105 | |

| ASTM A182 Gr. F316/ ASTM A351 Gr. CF8M | ||||

| 2 | Ball | ASTM A351 Gr. CF8M/ ASTM A182 Gr. F304/ ASTM A182 Gr. F316 | ||

| 3 | Seat | PTFE/ RPTFE/ Special filled PTFE/ PEEK/ Devlon®/ NXT-70/ SS316 + ST | ||

| 4 | Stem | ASTM A479 Type 316 | ||

| 5 | Body Seal | Graphite | PTFE/ RPTFE/ Special filled PTFE/ Graphite |

|

| 6 | Stem Thrust Seal | Carbon-filled PTFE | ||

| 7 | Stem Packing | Carbon-filled PTFE/ Graphite | ||

Check Dimension of Motorized, Electric and Full Port Brass Ball Valve for piping connection

`Trunnion Mounted Ball Valve Dimension Chart

Two-piece Ball Valves - Full Bore (ASME Class 150 & 300)

| Size | A | B | C | D | E | F | G | Wt. | ISO 5211 Base | |||||

| DN | NPS | Cl 150 | Cl 300 | Cl 150 | Cl 300 | Cl 150 | Cl 300 | Cl 150 | Cl 300 | |||||

| 15 | ½ | 108 | 140 | 90 | 95 | 13 | 11 | 38 | 120 | 90 | 1 | 2 | F03 | F03 |

| 20 | ¾ | 117 | 152 | 100 | 115 | 19 | 11 | 38 | 120 | 90 | 1 | 2.5 | F03 | F03 |

| 25 | 1 | 127 | 165 | 110 | 125 | 25 | 17 | 46 | 140 | 100 | 2 | 4 | F03 | F03 |

| 40 | 1½ | 165 | 190 | 125 | 155 | 38 | 27 | 56 | 180 | 115 | 4 | 4.5 | F04 | F04 |

| 50 | 2 | 178 | 216 | 150 | 165 | 51 | 37 | 75 | 210 | 122 | 6.5 | 9 | F05 | F05 |

| 65 | 2½ | 190 | 241 | 180 | 190 | 64 | 49 | 102 | 210 | 142 | 11 | 15 | F07 | F07 |

| 80 | 3 | 203 | 282 | 190 | 210 | 76 | 62 | 175 | 390 | 15.5 | 22 | F07 | F07 | |

| 100 | 4 | 229 | 305 | 230 | 255 | 102 | 74 | 195 | 390 | 25 | 35 | F07 | F07 | |

| 150 | 6 | 267 | 403 | 280 | 320 | 152 | 98 | 245 | * | 40 | 65 | F10 | F12 | |

Three-piece Ball Valves - Full Bore (ASME Class 150, 300, 600 & 2500)

| Size | A | B | C | D | E | F | G | Wt. | ISO 5211 Base | ||||||

| DN | NPS | Cl 150 | Cl 300 | Cl 150 | Cl 300 | Cl 150 | Cl 300 | Cl 150 | Cl 300 | Cl 150 | Cl 300 | ||||

| 15 | ½ | 108 | 140 | 90 | 95 | 13 | 11 | 38 | 38 | 120 | 90 | 1 | 2 | ||

| 20 | ¾ | 117 | 152 | 100 | 115 | 19 | 17 | 45 | 45 | 120 | 97 | 2 | 3 | ||

| 25 | 1 | 127 | 165 | 110 | 125 | 25 | 24 | 55 | 55 | 158 | 97 | 3 | 4 | ||

| 40 | 1½ | 165 | 190 | 125 | 155 | 38 | 37 | 75 | 75 | 212 | 122 | 5 | 6 | F05 | F05 |

| 50 | 2 | 178 | 216 | 150 | 165 | 51 | 49 | 103 | 103 | 212 | 142 | 9 | 12 | F07 | F07 |

| 65 | 2½ | 190 | 241 | 180 | 190 | 64 | 62 | 175 | 175 | 390 | 14 | 20.5 | F07 | F07 | |

| 80 | 3 | 203 | 282 | 190 | 210 | 76 | 74 | 185 | 195 | 390 | 19 | 28 | F07 | F07 | |

| 100 | 4 | 229 | 305 | 230 | 255 | 102 | 98 | 235 | 247 | * | 31 | 45 | F10 | F12 | |

| 150 | 6 | 394 | 403 | 280 | 320 | 152 | 148 | 285 | 315 | ** | 78 | 105 | F12 | F14 | |

| 200 | 8 | 457 | 502 | 345 | 380 | 203 | 198 | 345 | 371 | 980 | 141.5 | 169 | F14 | F16 | |

3 Way Ball Valves advantages

- Efficiency: Ball valves don’t need any lubrication, and offer a bubble-tight seal with low torque.

- Affordability: They can often be purchased at a considerably lower cost than comparable products for the same job.

- Durability: They offer a long service life and, when used under the right conditions, will provide many years of reliable use. Ball valves are less prone to damage than other kinds of valves, and the plastic variety aren’t susceptible to corrosion.

- Easy to use: Ball valves are relatively quick and easy to install, and plastic ball valves are light and easy to handle.

- Versatile: They’re appropriate for a wide range of industrial applications where it’s necessary to regulate the flow of liquids or gases.

- Strong: Ball valves can maintain and regulate high pressure, high volume and a high flow of temperature.

- Simple to repair: Easily access the seats when a valve requires fixing.

Disadvantages of Fully Welded Ball Valves

- Poor throttling characteristics: In a throttling position, the partially exposed seat may be prone to erosion as a result of high velocity flows. They’re therefore not recommended for sustained throttling applications.

- Wear and tear: When used to regulate the wrong types of fluids, such as slurries, ball valves can stick in position and become jammed due to suspended particles being trapped. This can cause the valve to wear, or to become damaged or stuck.

International Standards of Ball Check Valves

ASME STANDARDS

- ASME B16.5 - Pipe Flanged Fittings and Flanges: NPS 1/2 through 24

- ASME B16.10 - End to End & Face to Face Dimensions of Valves

- ASME B16.20 - Metallic Gaskets for Pipe Flanges: Spiral-Wound, Ring-Joint, and Jacketed

- ASME B16.25 - Buttwelding Ends

- ASME B16.34 - Valves Flanged, Welding, Threaded End

API STANDARDS

- API Spec 6D - Specification for End Closures, Pipeline Valves, Swivels and Connectors

- API Std 598 - Valve Test and Inspection

ISO STANDARDS

- ISO 7121 - Steel ball valve for general-purpose applications for industries

BSI STANDARDS

- BS 2080 - Specification for centre-to-face, face-to-face, centre-to-end and end-to-end dimensions of valves

- BS 5159 - Specification for carbon steel ball valves and cast iron for general purposes

- BS 5351 - Specification for steel ball valves for the petrochemical, petroleum and allied industries

MSS STANDARDS

- MSS-SP-61 - Pressure Testing of Steel Valves

- MSS-SP-72 - Ball Valves with Butt-Welding & Flanged Ends for General Service

- MSS-SP-84 - Steel Valves, Threaded Ends and Socket Welding

Ball Valve Vs Plug Valve

| Characteristics | Ball Valve | Plug Valve |

| Shape | Ball valves are a type of control valve with a spherical disc, which controls the flow through it | Plug valves are conically-tapered or cylindrical Plugs Shape. The Valve can be rotated inside the body to control flow through the valve |

| Flow | less Control flow | better control flow |

| Port | mostly full port | full port or reduced port |

| Size | small | large |

Ball Valves Uses

- gaseous, Air, and liquid applications requiring bubble-tight service

- high-point vents in liquid, Low-point drains and gaseous, and other fluid services

- Instrument root valves

- Cooling water and feed water systems

- Steam service

View Hydraulic and Pneumatic Ball Valve Actuator Temperature Range

Ball Valve Flange End Temperature Range

| Valve Type | Minimum Temperature |

Maximum Temperature |

||

|---|---|---|---|---|

| oC | oF | oC | oF | |

| Ball | -55 | -65 | 300 | 575 |

Check Price List of High Pressure, PVC and Fisher v150 Ball valves Importers

Ball Float Valve Price per Piece

| Ball Valve Prices | 2 Piece Ball Valve Price list |

|---|---|

| DN15 - DN100 Pressure PN25 Cw617n / HPB59-3 Nickel Plating Brass Ball Valve | US$ 1.70-US$ 2.00 / Pieces |

| Stainless Steel GB Standard Flange Ball Valve | US$ 21.99 / Pieces |

| 1/4-4 inch 2PC Stainless Steel Ball Valve Threaded Ends 1000WOG | US$ 1.91-US$ 1.99 / Piece |

| ball valves three way | US$ 15.00-US$ 200.00 / Set |

| Half Inch Forged Brass Ball Valve | US$ 0.98-US$ 1.00 / Piece |

Weight Chart of 3-Piece Trunnion Mounted Ball Valves - API 6D

Full PortClass: 2500

Sizes: 2" - 12"

| SIZE | BORE | END-TO-END | Body Dimensions | Trunnion | FLG Weights | BW Weights | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| F | A - RF | A - RTJ | A - WE | H1 | H2 | H3 | EXT | INT | LBS/KG | LBS/KG | ||

| IN | 1 x 1* | 1.00 | / | 14.0 | / | 3.78 | 7.56 | / | YES | / | 97 | / |

| MM | 25 x 25 | 25 | / | 356 | / | 96 | 192 | / | 36 | / | ||

| IN | 1.5 x 1.5* | 1.50 | / | 15.24 | / | 4.30 | 8.15 | / | YES | / | 130 | / |

| MM | 38 x 38 | 38 | / | 387 | / | 109 | 209 | / | 48 | / | ||

| IN | 2 x 2* | 2.00 | 17.75 | 17.875 | 17.75 | 4.44 | 7.28 | 10.90 | YES | / | 225 | 216 |

| MM | 50 x 50 | 51 | 451 | 454 | 451 | 113 | 185 | 277 | 115 | 98 | ||

| IN | 3 x 3* | 3.00 | 22.75 | 23.00 | 22.75 | 5.56 | 9.47 | 13.05 | YES | / | 440 | 374 |

| MM | 80 x 80 | 76 | 578 | 584 | 578 | 141 | 241 | 331 | 200 | 170 | ||

| IN | 4 x 4 | 4.00 | 26.50 | 26.875 | 26.50 | 6.50 | 10.34 | 13.92 | YES | / | 825 | 701 |

| MM | 100 x 100 | 102 | 673 | 682 | 673 | 165 | 263 | 354 | 370 | 314 | ||

| IN | 6 x 6 | 6.00 | 36.00 | 36.50 | 36.00 | 8.69 | 12.97 | 16.55 | / | YES | 1790 | 1521 |

| MM | 150 x 150 | 152 | 914 | 927 | 914 | 220 | 329 | 420 | 800 | 680 | ||

| IN | 8 x 8 | 8.00 | 40.25 | 40.875 | 40.25 | 10.38 | 15.58 | 19.10 | / | YES | 3500 | 2975 |

| MM | 200 x 200 | 203 | 1022 | 1038 | 1022 | 264 | 396 | 485 | 1600 | 1360 | ||

| IN | 10 x 10 | 10.00 | 50.00 | 50.875 | 50.00 | 12.13 | 17.41 | 21.74 | / | YES | 5400 | 4590 |

| MM | 250 x 250 | 254 | 1270 | 1292 | 1270 | 308 | 442 | 552 | 2500 | 2940 | ||

| IN | 12 x 12 | 12.00 | 56.00 | 56.875 | 56.00 | 13.88 | 19.47 | 23.80 | / | YES | 8300 | 7055 |

| MM | 300 x 300 | 305 | 1422 | 1444 | 1422 | 353 | 495 | 605 | 4000 | 3400 | ||

Ball Valves Stock Of Following Manufacturers in UAE

Ball Valve Stock in UAE

2-way Ball Valves Stocking Distributor in UAE

Stocking Distributor Of 3-way Ball Valves in UAE

Stock Of Motorized Ball Valves in UAE

Butterfly Ball Valves Stockist in Dubai

Stockholder Of Pneumatic Ball Valves in Dubai

Tank Bottom Ball Valves Stockholder in Dubai

Supplier Of Non Retention Ball Valves in Dubai

Supplier Of Two Way Ball Valve in UAE

Three Way Ball Valve Supplier in UAE

Stock of Forged Steel Floating Ball Valve in UAE

Threaded Ball Valve Stock in Dubai

Three Piece Body Ball Valve Stocking Distributor in Dubai

Stocking Distributor Of Side Entry Ball Valves in Dubai

Stock Of Reduced Bore Ball Valve in Dubai

Stockist Of Cast Iron Ball Valve in Dubai

Stockist Of Trunnion Ball Valves in UAE

Actuated Ball Valves Stockist in UAE

Stockholder Of Flanged Ball Valves in UAE

Multiport Ball Valves Stockholder in UAE

Ball Valve Actuator Supplier in Dubai

Stock of Electric Ball Valves in Dubai

Supplier Of Straight Ball Valve in UAE