70/30 Copper Nickel fittings Stockist, Check Cupro Nickel 70/30 Pipe Fittings Weight Chart in MM

Check Cu-Ni UNS C71500 Seamless Pipe Fittings Dimensions in MM, Looking to Buy ANSI B16.9 Copper Nickel 70/30 Elbow from Supplier

70/30 Copper Nickel Fittings

70/30 Copper Nickel Buttweld Pipe Fittings

Cu-Ni UNS C71500 Seamless Pipe Fittings

ANSI B16.9 Copper Nickel 70/30 Elbow

70/30 Cu-Ni Welded Pipe Fittings

Table of Content

- Specification of 70/30 Copper Nickel fittings

- Different types of Copper Nickel 70/30 Pipe Fittings

- Dimension Chart of Cu-Ni Uns C71500 Seamless Pipe Fittings

- Density of ANSI B16.9 Copper Nickel 70/30 Elbow

- ASTM B171 UNS C71500 Pipe Cap Chemical Behaviour

- Equivalent of 70/30 Cu-Ni Welded Pipe Fittings

- Copper Alloy 70 / 30 Reducer Price per Piece

- Mechanical Analysis of SB171 Copper Nickel 70/30 Fittings

- Cuni 70/30 Welded Tee Weight Chart

- ASTM B171 Copper Nickle Alloy 70/30 Elbow Pressure Rating

- European Standard of Cu Ni 70 30 Buttweld Elbow

- Copper Nickel Alloy 70/30 Buttweld Pipe Fittings Thermal Properties

- Temperature Range of Cupro Nickel 70/30 Buttweld Fittings

- Copper Alloy 70/30 Unequal Tee Electrical Properties

- UNS C71500 reducer Uses

- Fabrication Properties of UNS C71500 Short Radius Elbow

- Copper Nickel Alloy 70/30 Fittings Value Added Services

- Cu-Ni 70/30 Pipe Fittings Corrosion

- ASTM B171 UNS C71500 Pipe Cap Features

- Copper Nickel 70/30 Vs 90/10

Specification of 70/30 Copper Nickel fittings

| Grade | CU-NI-70/30 (UNS No C71500) |

|---|---|

| Standard | ASTM B122, B171, B466, B467 |

| Dimension Std. | ANSI/ASME B16.9, B16.28, MSS-SP-43 |

| Size | ½” NB – 12” NB |

| Type | Seamless / ERW / Welded / Fabricated |

| Schedule | SCH 10 – SCH XXS |

Different types of Copper Nickel 70/30 Pipe Fittings

Cuni 70/30 Welded Tee

Cupro Nickel Fittings / Cu-ni Pipe Fittings / Cu-ni(70/30) Fittings

C71500 Copper Nickel 70/30 Elbow 90 Deg 1/2 " Sch 10s Elbow Fittings

Cuni 70/30 Reducer

3/4" Sch Std 180 Degree Return Bend Copper Nickle Alloy 70/30 Elbow Pipe Fittings

Copper 70/30 90 Degree Elbow

Copper Nickel 70/30 Elbow 1 " 90 Deg Sch 10s Steel Pipe Fittings Elbow Fitting

Cuni C71500 Copper Nickel 70/30 Pipe Fitting 45d 1-1/2" Elbow Sch40 Asme B16.9

Check Dimension Chart of ASTM B171 UNS C71500 Pipe Cap, Largest Importers of 70/30 Cu-Ni Welded Pipe Fittings

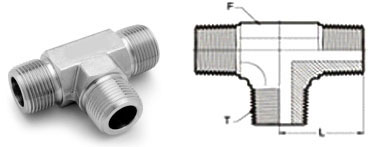

Dimension Chart of Cu-Ni Uns C71500 Seamless Pipe Fittings

| SIZE | F A/F |

T NPT(F) |

L |

|---|---|---|---|

| 1/8” | 1/8” | 1/2” | 0.75 |

| 1/4” | 1/4” | 9/16” | 0.87 |

| 3/8” | 3/8” | 11/16” | 0.94 |

| 1/2” | 1/2” | 7/8” | 1.30 |

| 3/4” | 3/4” | 1-1/16” | 1.38 |

Density of ANSI B16.9 Copper Nickel 70/30 Elbow

| Properties | Metric | Imperial |

|---|---|---|

| Density | 8.94 g/cm3 | 0.323 lb/in3 |

ASTM B171 UNS C71500 Pipe Cap Chemical Behaviour

| Cu-Ni 70/30 | Cu | Pb | Mn | Fe | Zn | Ni |

| 88.6 min | 0.05 max | 1.0 max | 1.8 max | 1 max | 9-11 max |

Equivalent of 70/30 Cu-Ni Welded Pipe Fittings

| STANDARD | UNS | WERKSTOFF NR. |

| Cupro Nickel 70/30 | C71500 | 2.0882 |

Purchase Alloy 70/ 30 Reducer at best Price, SB171 Copper Nickel 70/30 Fittings, Ask For ready stock of Cupro Nickel 70/30 Pipe Fittings

Copper Alloy 70 / 30 Reducer Price per Piece

| Cupro Nickel 70/30 Pipe Fittings Price Per Piece | Cu Ni 70/30 Weld Fittings Price |

| Copper Nickel 70/30 Pipe Fittings Price | $ 8.44 /Unit |

| Cupro Nickel 70/30 Elbow Price | $ 18.94 /Unit |

| Cu Ni 70/30 Buttweld Fittings Price | $ 44.16 /Unit |

| Copper Alloy 70/30 Fitting Price List | $ 27.97 /Unit |

Mechanical Properties of Cu-Ni WERKSTOFF NR. 2.0882 Tee, Check Cupro Nickel 70/30 Buttweld Fittings, 70/30 Cuni Long Stub End Size Chart

Mechanical Analysis of SB171 Copper Nickel 70/30 Fittings

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 8.1 g/cm3 | 1443 °C (2430 °F) | Psi – 35,000, MPa – 241 | Psi -80,000, MPa -551 | 30 % |

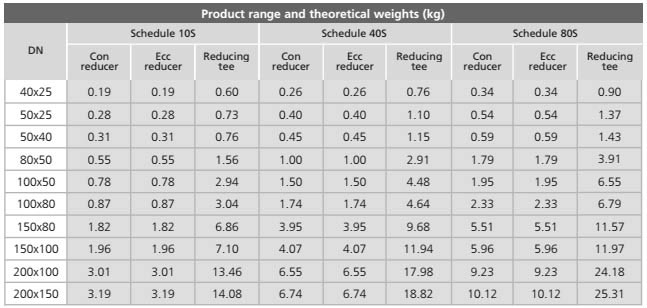

Cuni 70/30 Welded Tee Weight Chart

ASTM B171 Copper Nickle Alloy 70/30 Elbow Pressure Rating

| Normal Size Of Pipe (inches) |

Pipe Sch | OD (inch) |

Wall Thick. (inch) |

Temperature (oF) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 100 | 200 | 300 | 400 | 500 | 600 | 650 | 700 | 750 | ||||

| Allowable Stress (psi) | ||||||||||||

| 16700 | 16700 | 16700 | 15500 | 14400 | 13500 | 13200 | 12900 | 12600 | ||||

| 1" | 40 | 1.315 | 0.133 | 2205 | 2205 | 2205 | 2047 | 1902 | 1783 | 1743 | 1703 | 1664 |

| 80 | 1.315 | 0.179 | 3061 | 3061 | 3061 | 2841 | 2640 | 2475 | 2420 | 2365 | 2310 | |

| 160 | 1.315 | 0.250 | 4493 | 4493 | 4493 | 4170 | 3874 | 3632 | 3552 | 3471 | 3390 | |

| 1 1/2" | 40 | 1.900 | 0.145 | 1629 | 1629 | 1629 | 1512 | 1404 | 1317 | 1287 | 1258 | 1229 |

| 80 | 1.900 | 0.200 | 2303 | 2303 | 2303 | 2138 | 1986 | 1862 | 1821 | 1779 | 1738 | |

| 160 | 1.900 | 0.281 | 3362 | 3362 | 3362 | 3120 | 2899 | 2717 | 2657 | 2597 | 2536 | |

| 2" | 40 | 2.375 | 0.154 | 1371 | 1371 | 1371 | 1272 | 1182 | 1108 | 1083 | 1059 | 1034 |

| 80 | 2.375 | 0.218 | 1985 | 1985 | 1985 | 1843 | 1712 | 1605 | 1569 | 1534 | 1498 | |

| 160 | 2.375 | 0.344 | 3283 | 3283 | 3283 | 3047 | 2831 | 2654 | 2595 | 2536 | 2477 | |

| 3" | 40 | 3.500 | 0.216 | 1301 | 1301 | 1301 | 1208 | 1122 | 1052 | 1028 | 1005 | 982 |

| 80 | 3.500 | 0.300 | 1844 | 1844 | 1844 | 1712 | 1590 | 1491 | 1458 | 1425 | 1391 | |

| 160 | 3.500 | 0.438 | 2787 | 2787 | 2787 | 2587 | 2403 | 2253 | 2203 | 2153 | 2103 | |

| 4" | 40 | 4.500 | 0.237 | 1102 | 1102 | 1102 | 1023 | 950 | 891 | 871 | 851 | 831 |

| 80 | 4.500 | 0.337 | 1596 | 1596 | 1596 | 1482 | 1377 | 1291 | 1262 | 1233 | 1204 | |

| 160 | 4.500 | 0.531 | 2611 | 2611 | 2611 | 2424 | 2552 | 2111 | 2064 | 2017 | 1970 | |

| 5" | 40 | 5.563 | 0.258 | 965 | 965 | 965 | 896 | 832 | 780 | 763 | 746 | 728 |

| 80 | 5.563 | 0.375 | 1428 | 1428 | 1428 | 1325 | 1231 | 1154 | 1129 | 1103 | 1077 | |

| 160 | 5.563 | 0.625 | 2474 | 2474 | 2474 | 2296 | 2133 | 2000 | 1955 | 1911 | 1866 | |

| 6" | 40 | 6.625 | 0.280 | 877 | 877 | 877 | 814 | 756 | 709 | 693 | 677 | 661 |

| 80 | 6.625 | 0.432 | 1379 | 1379 | 1379 | 1280 | 1189 | 1115 | 1090 | 1065 | 1040 | |

| 160 | 6.625 | 0.719 | 2382 | 2382 | 2382 | 2211 | 2054 | 1925 | 1883 | 1840 | 1797 | |

| 8" | 40 | 8.625 | 0.322 | 771 | 771 | 771 | 716 | 665 | 623 | 610 | 596 | 582 |

| 80 | 8.625 | 0.500 | 1218 | 1218 | 1218 | 1131 | 1050 | 985 | 963 | 941 | 919 | |

| 160 | 8.625 | 0.906 | 2298 | 2298 | 2298 | 2133 | 1982 | 1858 | 1817 | 1775 | 1734 | |

| 10" | 40 | 10.750 | 0.365 | 699 | 699 | 699 | 649 | 603 | 565 | 553 | 540 | 528 |

| 80 | 10.750 | 0.594 | 1159 | 1159 | 1159 | 1075 | 999 | 937 | 916 | 895 | 874 | |

| 160 | 10.750 | 1.125 | 2289 | 2289 | 2289 | 2124 | 1974 | 1850 | 1809 | |||

European Standard of Cu Ni 70 30 Buttweld Elbow

| BUTT WELD FITTINGS 90/10 | EEMUA | DIN | ANSI |

|---|---|---|---|

| ELBOWS LONG RADIUS | 146 SECTION 1 | DIN 86090 | B 16-9 |

| ELBOWS SHORT RADIUS | B 16-28 | ||

| EQUAL TEES | 146 SECTION 1 | DIN 86088 | B 16-9 |

| REDUCING TEES | 146 SECTION 1 | DIN 86088 | B 16-9 |

| CONCENTRIC REDUCERS | 146 SECTION 1 | DIN 86089 | B 16-9 |

| ECCENTRIC REDUCERS | 146 SECTION 1 | DIN 86089 | B 16-9 |

| EQUAL SADDLES | 146 SECTION 1 | DIN 86087 | |

| REDUCING SADDLES | 146 SECTION 1 | DIN 86087 | |

| END CAPS | 146 SECTION 1 | DIN 28011 | B 16-9 |

Copper Nickel Alloy 70/30 Buttweld Pipe Fittings Thermal Properties

| Thermal Conductivity | W/m°K | 29 |

|---|

Temperature Range of Cupro Nickel 70/30 Buttweld Fittings

| Specific Heat | J/kg °K | 377 |

|---|

Copper Alloy 70/30 Unequal Tee Electrical Properties

| Electrical Resistivity | microhm. cm | 34 |

|---|

UNS C71500 reducer Uses

- Petrochemical Industry

- Oil and Gas Industry

- Chemical Industry

- Power Plant Industry

- Energy Industry

Fabrication Properties of UNS C71500 Short Radius Elbow

Joining Technique |

Suitability |

|---|---|

Soldering |

Excellent |

Brazing |

Excellent |

Oxyacetylene Welding |

Fair |

Gas Shielded Arc Welding |

Excellent |

Coated Metal Arc Welding |

Good |

Spot Weld |

Good |

Seam Weld |

Good |

Butt Weld |

Excellent |

Capacity for Being Cold Worked |

Good |

Capacity for Being Hot Formed |

Good |

Machinability Rating |

20 |

Copper Nickel Alloy 70/30 Fittings Value Added Services

- Sand Blasting

- Electro Polish

- Epoxy Coating

Cu-Ni 70/30 Pipe Fittings Corrosion

Copper-nickel Alloys have good resistance to crevice corrosion and chloride pitting. They have good corrosion resistance against moisture, non-oxidising acids, alkalis and salt solutions, organic acids and to gases such as oxygen, hydrogen chloride, chlorine, hydrogen fluoride, carbon dioxide and sulphur dioxide .

ASTM B171 UNS C71500 Pipe Cap Features

- Corrosion resistant

- Durable functioning

- Malleable

- Heat resistance

- High strength

- Excellent conductivity

- Impeccable finish

- Enhanced service life

- Precisely designed

Copper Nickel 70/30 Vs 90/10

Check Chemical and Mechanical Properties| Element | Cu - Ni 90/10 Fitting | Cu - Ni 70/30 Fitting |

| Cu | 88.6 min | 65.0 min |

| Pb | .05 max | .05 max |

| Mn | 1.0 max | 1.0 max |

| Fe | 1.8 max | 0.4-1.0 |

| Zn | 1 max | 1 max |

| Ni | 9-11 max | 29 - 33 |

| Element | Copper Nickel 90/10 Fittings | Copper Nickel 70/30 Fitting |

| Density | 8.1 g/cm3 | 0.323 lb/in3 at 68 F |

| Melting Point | 1443 °C (2430 °F) | 2260 F |

| Tensile Strength | Psi -80,000, MPa -551 | 50000 psi |

| Yield Strength (0.2%Offset) | Psi - 35,000, MPa - 241 | 20000 psi |

| Elongation | 30 % | 30 % |