Schedule 40 API 5L PSL2 Line Pipe Supplier

Buy API 5L ERW Pipe in PSL1 and PSL2 at best price

API 5L Seamless Pipe

API 5L Material

API 5L Seamless Line Pipe

Table of Content

- API 5L Pipe Specifications Chart

- API 5L Seamless Pipe Types

- API 5L Seamless Line Pipe Weight

- API 5L Pipe Schedule Chart

- API 5L Schedule 40 Pipe Pressure Rating

- API 5L Carbon Steel Pipe Chemical Composition

- Thickness of API 5L Carbon Steel Seamless Pipe

- Length of Carbon Steel API 5L Welded Pipe

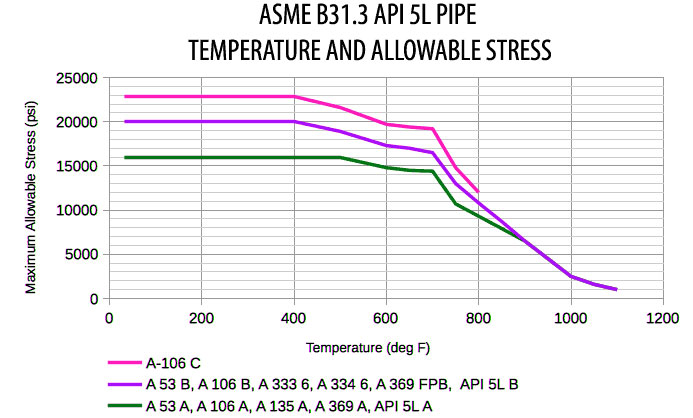

- API 5L Pipe Allowable Stress

- API 5L Schedule 60 Pipe Tolerance

- Useful Information of API 5L PSL1 Pipe

- Size Chart of API 5L PSL2 Pipe

- CS API 5L Pipe Grades

- API 5L Tube Mechanical Properties

- API 5L Dsaw Pipes Sizes

- API 5L LSAW Pipes Prices

- Api 5l Pipe Vs Astm A106 Gr.b

API 5L Pipe Specifications Chart

Check API 5L Erw Pipe Specification

| API 5L Steel Pipe Specification | ||

| API 5L Dsaw Pipe Type | Seamless steel pipe | |

| API 5L Lsaw Pipe Material | GR.B, X42, X52, X60 | |

| Erw Steel Pipe API 5L Application | Line pipe | |

| Seamless Steel Pipe API 5L Special pipe | Regular and special thick-walled steel pipe, maximum thickness of up to 60MM | |

| Carbon Steel API 5L Psl2 Pipe Process | Hot rolled and hot expanded | |

| Specification in Milimeter | 114-914MM*4-60MM | |

| API 5L Pipe Diameter in Milimeter | 114MM-914MM | |

| CS API 5L Galvanized Pipe Thickness in Milimeter | 4MM-60MM | |

| API 5L Line Pipe Length | As your requirements | |

API 5L Seamless Pipe Types

CS Gr.B SCH 40 smls steel line pipes

Carbon steel API 5L seamless line pipes

API 5l smls carbon steel pipes

API 5L PSL2 mild seamless steel pipes

Carbon Steel 5L 12Inch SCH40 smls Line Pipes

Carbon steel seamless pipes 5L, 160-315mm pipes line

Carbon Steel 5l hot rolled smls steel pipes 150mm diameter

34mm cs 5L smls steel pipes

5L Grade PSL2 smls Carbon steel line pipes

5l seamless line pipes

Carbon Steel 5L LSAW steel line pipes

Check API 5L lsaw Pipe, ISO 3183 Welded Pipes Dimension & Weight Chart

API 5L Seamless Line Pipe Weight

| NPS | Outside Diameter | Wall Thickness | Weight | Weight | |||

| in | mm | in | mm | Sched | kg/Mtr | Lb/ft | |

| 1/2″ | 0.840 | 21 | 0.109 | 2.769 | 40 STD | 1.268 | 0.851 |

| 0.147 | 3.734 | 80 STD | 1.621 | 1.088 | |||

| 3/4″ | 1.050 | 27 | 0.113 | 2.870 | 40 STD | 1.684 | 1.131 |

| 0.154 | 3.912 | 80 STD | 2.195 | 1.474 | |||

| 1″ | 1.315 | 33 | 0.133 | 3.378 | 40 STD | 2.501 | 1.679 |

| 0.179 | 4.547 | 80 STD | 3.325 | 2.172 | |||

| 1 1/4″ | 1.660 | 42 | 0.140 | 3.556 | 40 STD | 3.385 | 2.273 |

| 0.191 | 4.851 | 80 STD | 4.464 | 2.997 | |||

| 1 1/2″ | 1.900 | 48 | 0.145 | 3.683 | 40 STD | 4.048 | 2.718 |

| 0.200 | 5.080 | 80 STD | 5.409 | 3.361 | |||

| 2″ | 2.375 | 60 | 0.154 | 3.912 | 40 STD | 5.441 | 3.653 |

| 0.218 | 5.537 | 80 STD | 7.480 | 5.022 | |||

| 2 1/2″ | 2.875 | 73 | 0.203 | 5.516 | 40 STD | 8.629 | 5.793 |

| 0.276 | 7.010 | 80 STD | 11.411 | 7.661 | |||

| 3″ | 3.500 | 89 | 0.216 | 5.486 | 40 STD | 11.284 | 7.576 |

| 0.300 | 7.620 | 80 STD | 15.272 | 10.253 | |||

| 4″ | 4.500 | 114 | 0.237 | 6.020 | 16.073 | 10.790 | |

| 0.337 | 8.560 | 22.318 | 14.983 | ||||

| 6″ | 6.625 | 168 | 0.188 | 4.775 | 19.252 | 12.924 | |

| 0.203 | 5.516 | 20.739 | 13.923 | ||||

| 0.219 | 5.563 | 22.318 | 14.983 | ||||

| 0.250 | 6.350 | 25.354 | 17.021 | ||||

| 0.280 | 7.112 | 40 STD | 58.263 | 18.974 | |||

| 0.312 | 7.925 | 31.334 | 21.036 | ||||

| 0.375 | 9.525 | 37.285 | 25.031 | ||||

| 0.432 | 10.973 | 80 XHY | 42.561 | 28.573 | |||

| 0.500 | 12.700 | 48.719 | 32.708 | ||||

| 8″ | 8.625 | 219 | 0.188 | 4.775 | 25.233 | 16.940 | |

| 0.203 | 5.156 | 27.198 | 18.259 | ||||

| 0.219 | 5.563 | 29.286 | 19.661 | ||||

| 0.250 | 6.350 | 20 | 33.308 | 22.361 | |||

| 0.277 | 7.036 | 30 | 36.786 | 24.696 | |||

| 0.322 | 8.179 | 40 | 42.352 | 28.554 | |||

| 0.375 | 9.525 | 49.216 | 33.041 | ||||

| 0.406 | 10.312 | 60 | 53.085 | 35.638 | |||

| 0.500 | 12.700 | 80 XHY | 64.627 | 43.388 | |||

| 10″ | 10.750 | 273 | 0.188 | 4.775 | 31.588 | 21.207 | |

| 0.219 | 5.563 | 36.689 | 24.631 | ||||

| 0.250 | 6.350 | 20 | 41.759 | 28.035 | |||

| 0.307 | 7.798 | 30 | 51.002 | 34.240 | |||

| 0.344 | 8.738 | 56.946 | 38.231 | ||||

| 0.365 | 9.271 | 40 STD | 63.301 | 40.483 | |||

| 0.438 | 11.125 | 71.852 | 48.238 | ||||

| 0.500 | 12.700 | 60 XHY | 81.530 | 54.735 | |||

| 0.594 | 15.088 | 80 | 95.969 | 64.429 | |||

| 12″ | 12.750 | 324 | 0.188 | 4.775 | 37.570 | 25.222 | |

| 0.219 | 5.563 | 43.657 | 29.309 | ||||

| 0.250 | 6.350 | 49.713 | 33.375 | ||||

| 0.281 | 7.137 | 55.739 | 37.420 | ||||

| 0.312 | 7.925 | 61.735 | 41.445 | ||||

| 0.375 | 9.525 | 73.824 | 49.562 | ||||

| 0.406 | 10.312 | 79.727 | 53.525 | ||||

| 0.500 | 12.700 | 97.438 | 65.415 | ||||

| 0.562 | 14.275 | 108.966 | 73.154 | ||||

| 14″ | 14.000 | 356 | 0.188 | 4.775 | 41.308 | 27.732 | |

| 0.219 | 5.563 | 48.012 | 32.233 | ||||

| 0.250 | 6.350 | 20 | 54.685 | 36.713 | |||

| 0.281 | 7.137 | 61.327 | 41.172 | ||||

| 0.312 | 7.925 | 67.939 | 45.611 | ||||

| 0.375 | 9.525 | STD | 81.281 | 54.568 | |||

| 0.438 | 11.125 | 40 | 94.498 | 63.441 | |||

| 0.500 | 12.700 | XHY | 107.381 | 72.090 | |||

| 0.625 | 15.875 | 132.983 | 89.278 | ||||

| 16” | 16.000 | 406 | 0.188 | 4.775 | 47.290 | 21.748 | |

| 0.219 | 5.563 | 54.980 | 36.910 | ||||

| 0.250 | 6.350 | 10 | 62.639 | 42.053 | |||

| 0.281 | 7.137 | 70.268 | 47.174 | ||||

| 0.312 | 7.925 | 20 | 77.866 | 52.275 | |||

| 0.344 | 8.738 | 85.677 | 57.519 | ||||

| 0.375 | 9.525 |

30 STD |

93.213 | 62.578 | |||

| 0.438 | 11.125 | 108.433 | 72.797 | ||||

| 0.500 | 12.700 |

40 XHY |

123.289 | 82.770 | |||

| 18″ | 18.000 | 457 | 0.219 | 5.563 | 61.948 | 41.588 | |

| 0.250 | 6.350 | 70.593 | 47.393 | ||||

| 0.281 | 7.137 | 79.208 | 53.176 | ||||

| 0.312 | 7.925 | 20 | 87.792 | 58.939 | |||

| 0.375 | 9.525 | STD | 105.144 | 70.588 | |||

| 0.438 | 11.125 | 30 | 122.369 | 82.152 | |||

| 0.500 | 12.700 | XHY | 139.198 | 93.450 | |||

| 0.562 | 14.275 | 40 | 155.904 | 104.666 | |||

| 0.625 | 15.875 | 172.754 | 115.978 | ||||

| 20″ | 20.000 | 508 | 0.250 | 6.350 | 78.547 | 52.733 | |

| 0.282 | 7.163 | 88.458 | 59.386 | ||||

| 0.312 | 7.925 | 97.719 | 65.604 | ||||

| 0.375 | 9.525 | 20 STD | 117.075 | 78.598 | |||

| 0.438 | 11.125 | 136.305 | 91.508 | ||||

| 0.500 | 12.700 | 30 XHY | 155.106 | 104.130 | |||

| 0.594 | 15.088 | 40 | 183.378 | 123.110 | |||

| 0.625 | 15.875 | 192.640 | 129.328 | ||||

| 0.688 | 17.475 | 211.368 | 141.901 | ||||

| 24″ | 24.000 | 610 | 0.250 | 6.350 | 94.456 | 63.413 | |

| 0.281 | 7.137 | 106.029 | 71.183 | ||||

| 0.312 | 7.925 | 117.573 | 18.932 | ||||

| 0.375 | 9.525 | 20 STD | 140.938 | 64.618 | |||

| 0.438 | 11.125 | 164.176 | 110.219 | ||||

| 0.500 | 12.700 | XHY | 186.923 | 125.490 | |||

| 0.625 | 15.875 | 232.410 | 156.028 | ||||

| 0.688 | 17.475 | 40 | 255.148 | 171.293 | |||

| 0.750 | 19.050 | 277.401 | 186.233 | ||||

| 30″ | 30.000 | 762 | 0.250 | 6.350 | 118.318 | 79.433 | |

| 0.281 | 7.137 | 132.851 | 89.189 | ||||

| 0.312 | 7.925 | 10 | 147.353 | 98.925 | |||

| 0.375 | 9.525 | STD | 176.731 | 118.648 | |||

| 0.438 | 11.125 | 205.983 | 138.286 | ||||

| 0.500 | 12.700 | 20 XHY | 234.647 | 157.530 | |||

| 0.625 | 15.875 | 30 | 292.066 | 196.078 | |||

| 0.688 | 17.475 | 320.817 | 215.380 | ||||

| 0.750 | 19.050 | 348.988 | 234.293 | ||||

| 36″ | 36.000 | 914 | 0.250 | 6.350 | 142.180 | 95.453 | |

| 0.281 | 7.137 | 159.672 | 107.196 | ||||

| 0.312 | 7.925 | 10 | 177.133 | 118.918 | |||

| 0.375 | 9.525 | STD | 215.525 | 142.678 | |||

| 0.438 | 11.125 | 247.790 | 166.353 | ||||

| 0.500 | 12.700 | 20 XHY | 282.372 | 198.570 | |||

| 0.625 | 15.875 | 351.723 | 236.128 | ||||

0.688 |

17.475 | 386.487 | 259.467 | ||||

0.750 |

19.050 | 420.576 | 282.353 | ||||

| 42″ | 42.000 | 1067 | 0.312 | 7.925 | 206.914 | 138.911 | |

| 0.375 | 9.525 | STD | 248.319 | 166.708 | |||

| 0.500 | 12.700 | XHY | 33.097 | 221.610 | |||

| 0.750 | 19.050 | 492.163 | 330.413 | ||||

| 48″ | 48.000 | 1219 | 0.375 | 9.525 | STD | 284.112 | 190.738 |

| 0.438 | 11.125 | 331.404 | 222.487 | ||||

| 0.500 | 12.700 | XHY | 377.822 | 253.650 | |||

| 0.750 | 19.050 | 563.750 | 378.473 | ||||

| 0.875 | 22.225 | 655.969 | 440.383 | ||||

API 5L Pipe Schedule Chart

| 1/8" IPS(.405" O.D.) | 3 1/2" IPS( 4.000" O.D.) |

|---|---|

| SCH 40, 80 | SCH 10, 40, 80, 160, XXH |

| 1/4" IPS(.540" O.D.) | 4" IPS(4.500" O.D.) |

| SCH 10, 40, 80 | SCH 10, 40, 80, 160, XXH |

| 3/8" IPS(.675" O.D.) | 5" IPS( 5.563" O.D.) |

| SCH 10, 40, 80 | SCH 10, 40, 80, 160, XXH |

| 1/2" IPS(.840" O.D.) | 6" IPS(6.625" O.D.) |

| SCH 5, 10, 40, 80, 160, XXH | SCH 5, 10, 40, 80, 120, 160, XXH |

| 3/4" IPS(1.050" O.D.) | 8 ” IPS(8.625" O.D.) |

| SCH 10, 40, 80, 160, XXH | SCH 5, 10, 40, 80, 120, 160, XXH |

| 1" IPS:(1.315′ O.D.) | 10" IPS(10.750" O.D.) |

| SCH 5, 10, 40, 80, 160, XXH | SCH 10, 20, 40, 80 (.500), TRUE 80(.500) |

| 1-1/4" IPS(1.660" O.D.) | 12" IPS(12.750" O.D.) |

| SCH 10, 40, 80, 160, XXH | SCH 10, 20, 40(.375), TRUE40(.406), SCH80(.500) |

| 1-1/2" IPS(1.900" O.D.) | 14" IPS(14.000" O.D.) |

| SCH 10, 40, 80, 160, XXH | SCH10 (.188), SCH40 (.375) |

| 2" IPS(2.375" O.D.) | 16" IPS(16.000" O.D.) |

| SCH 10, 40, 80, 160, XXH | SCH10(.188), SCH40(.375) |

| 2 1/2" IPS(2.875" O.D.) | 18" IPS (18.000" O.D.) |

| SCH 10, 40, 80, 160, XXH | SCH-40 (.375) |

| 3" IPS( 3.500" O.D.) | |

| SCH 5, 10, 40, 80, 160, XXH |

API 5L Schedule 40 Pipe Pressure Rating

| Pipe O.D. (in.) |

API 5L Pipes Thickness Chart in (inches) | |||||||

|---|---|---|---|---|---|---|---|---|

| .028 | .035 | .049 | .065 | .083 | .095 | .109 | .120 | |

| Working Pressure (psig) | ||||||||

| 1/8 | 7900 | 10100 | ||||||

| 1/4 | 3700 | 4800 | 7000 | 9500 | ||||

| 5/16 | 3700 | 5400 | 7300 | |||||

| 3/8 | 3100 | 4400 | 6100 | |||||

| 1/2 | 2300 | 3200 | 4400 | |||||

| 3/4 | 2200 | 3000 | 4000 | 4600 | ||||

| 1 | 2200 | 2900 | 3400 | 3900 | 4300 | |||

API 5L Carbon Steel Pipe Chemical Composition

| Grades | Chemical Composition | |||||||

| C | Si | Mn | P | S | V | Nb | Ti | |

| X42 | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 |

| X52 | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 |

| X60 | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.08 | 0.05 | 0.04 |

| X65 | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.09 | 0.05 | 0.06 |

| X70 | 0.17 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.05 | 0.06 |

Thickness of API 5L Carbon Steel Seamless Pipe

| 5L Line Pipe Wall Thickness Chart mm (in) | CS 5L Drill Pipe Tolerances mm (in) mm (in) |

| SMLS pipes b | |

| ≤ 4,0 ( 0.157) | + 0,6 (0.024) - 0,5 (0.020) |

| > 4,0 ( 0.157) to < 25,0 (0.984) | + 0,150 - 0,125 |

| ≥ 25,0 (0.984) | +3,7 (0.146) or + 0,1 t whichever is the greater - 3,0 (0.120) or - 0,1 t whichever is the greater |

Length of Carbon Steel API 5L Welded Pipe

CS API 5L Pipe Length

| Threaded & Coupled Pipes | Shortest Length in Entire Shipment | Shortest Length in 95% of Entire Shipment | Minimum Average Length of Entire Shipment |

|---|---|---|---|

| Single Random | 16' 0" | 18' 0" | -- |

| Double Random | 22' 0" | -- | 35' 0" |

API 5L Pipe Allowable Stress

View Carbon Steel API 5L Pipe Temperature

API 5L Schedule 60 Pipe Tolerance

| Specified outside diameter D mm (in) of API 5L Pipes | Diameter tolerances Milimeter (in) | Out-of-roundness tolerances Milimeter (in) | ||||

| Pipes except at end a | Pipes end a,b,c | Pipes except at end a | Pipes end a,b,c | |||

| SMLS pipes | Welded pipes | SMLS pipes | Welded pipes | |||

| < 60.3 (2.375) | - 0.8 (0.031 ) to + 0.4 (0.016) | - 0.4 (0.016) to + 1.6 (0.063) | d | |||

| ≥ 60.3 (2.375) to ≤ 168.3 (6.625) | ± 0.007 5 D | 0.020 D | 0.015 D | |||

| ≥ 168.3 (6.625) to ≤ 610 (24.00) | ± 0.007 5 D | ± 0.007 5 D but maximum of + 3.2 (0.125) | ± 0.005 D, but maximum of ± 1.6 (0.063) | |||

| > 610 (24.000) to ≤ 1 422 (56.00) | ± 0.01 D | ± 0.005 D, but maximum of + 4.0 (0.160) | ± 2.0 (0.079) | ± 1.6 (0.063) | 0.015 D | 0.01 D, |

| but maximum of 15 (0.6), | but maximum of 13 (0.5), | |||||

| for d / ts ≤ 75 | for d / ts ≤ 75 | |||||

| by agreement | by agreement | |||||

| for d / ts > 75 | for d / ts > 75 | |||||

| > 1 422 (56 000) | as agreed | |||||

Useful Information of API 5L PSL1 Pipe

| SR3 | Color Identification. |

| SR4 | Nondestructive Inspection of Seamless Pipes. |

| SR5 | Charpy impact Testing - Welded Pipes 20" & larger - Grade X52 or higher. |

| SR6 | Drop Weight Tear Testing - Welded Pipes 20" & larger -Grade X52 or higher. |

| SR8 | Fracture Tough ness Testing of Line Pipes. |

Size Chart of API 5L PSL2 Pipe

Carbon Steel API 5L Pipe Sizes Metric

| Wall | Sizes ( O.D.) |

|---|---|

| .010 | 1/16" , 1/8" , 3/16" |

| .020 | 1/16" , 1/8" , 3/16" , 1/4" , 5/16" , 3/8" |

| .012 | 1/8" |

| .016 | 1/8" , 3/16" |

| .028 | 1/8" , 3/16" , 1/4" , 5/16" , 3/8" , 1/2" , 3/4" , 1" , 1 1/2" , 2" |

| .035 | 1/8" , 3/16" , 1/4" , 5/16" , 3/8" , 7/16" , 1/2" , 16" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 1 5/8" , 2" , 2 1/4" |

| .049 | 3/16" , 1/4" , 5/16" , 3/8" , 1/2" , 16" , 5/8" , 3/4" , 7/8" , 1" , 1 1/8" , 1 1/4" , 1 1/2" , 1 5/8" , 2" , 2 1/4" |

| .065 | 1/4" , 5/16" , 3/8" , 1/2" , 16" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 1 5/8" , 1 3/4" , 2" , 2 1/2" , 3" |

| .083 | 1/4" , 3/8" , 1/2" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 1 5/8" , 1 7/8" , 2" , 2 1/2" ,3" |

| .095 | 1/2" , 5/8" , 1" , 1 1/4" , 1 1/2" , 2" |

| .109 | 1/2" , 3/4" , 1" , 1 1/4" , 1 1/2" , 2" |

| .120 | 1/2" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 2" , 2 1/4" , 2 1/2" , 3" |

| .125 | 3/4" , 1" , 1 1/4" , 1 1/2" , 2" , 3" , 3 1/4" |

| .134 | 1" |

| .250 | 3" |

| .375 | 3 1/2" |

CS API 5L Pipe Grades

View API 5l Boiler Tube & Heat Exchanger Pipe Mechanical Properties

API 5L Tube Mechanical Properties

| API 5L Pipe Yield Strength | ||||

| Grades | Yield Strength | Tensile Strength | Yield to Tensile | Elongation |

| min. (KSI) | min. (KSI) | Ratio (max) | % | |

| X42 | 42 | 60 | 0.93 | 23 |

| X52 | 52 | 66 | 0.93 | 21 |

| X60 | 60 | 75 | 0.93 | 23 |

| X65 | 65 | 77 | 0.93 | 18 |

| X70 | 70 | 82 | 0.93 | 17 |

API 5L Dsaw Pipes Sizes

| API 5L Seamless Line Pipe OD mm |

Pipe WT mm |

in. | Sch | Kg/m |

|---|---|---|---|---|

| 13.72 | 1.65 | 1/4 | 10S | 0.50 |

| 13.72 | 2.24 | 1/4 | 40S | 0.64 |

| 13.72 | 3.02 | 1/4 | 80S | 0.81 |

| 17.15 | 1.65 | 3/8 | 10S | 0.64 |

| 17.15 | 2.31 | 3/8 | 40S | 0.86 |

| 17.15 | 3.20 | 3/8 | 80S | 1.12 |

| 21.34 | 2.11 | 1/2 | 10S | 1.02 |

| 21.34 | 2.77 | 1/2 | 40S | 1.29 |

| 21.34 | 3.73 | 1/2 | 80S | 1.65 |

| 26.67 | 2.11 | 3/4 | 10S | 1.30 |

| 26.67 | 2.87 | 3/4 | 40S | 1.71 |

| 26.67 | 3.91 | 3/4 | 80S | 2.23 |

| 33.40 | 2.77 | 1 | 10S | 2.13 |

| 33.40 | 3.38 | 1 | 40S | 2.54 |

| 33.40 | 4.55 | 1 | 80S | 3.29 |

| 33.40 | 6.352) | 1 | 160 | 4.30 |

| 42.16 | 2.77 | 1¼ | 10S | 2.73 |

| 42.16 | 3.56 | 1¼ | 40S | 3.44 |

| 42.16 | 4.85 | 1¼ | 80S | 4.53 |

| 42.16 | 6.352) | 1¼ | 160 | 5.69 |

| 48.26 | 2.77 | 1½ | 10S | 3.16 |

| 48.26 | 3.68 | 1½ | 40S | 4.11 |

| 48.26 | 5.08 | 1½ | 80S | 5.49 |

| 60.33 | 2.77 | 2 | 10S | 3.99 |

| 60.33 | 3.91 | 2 | 40S | 5.52 |

| 60.33 | 5.54 | 2 | 80S | 7.60 |

| 60.33 | 8.742) | 2 | 160 | 11.29 |

| 73.03 | 3.05 | 2½ | 10S | 5.35 |

| 73.03 | 5.16 | 2½ | 40S | 8.77 |

| 73.03 | 7.01 | 2½ | 80S | 11.59 |

| 88.90 | 3.05 | 3 | 10S | 6.56 |

| 88.90 | 5.49 | 3 | 40S | 11.47 |

| 88.90 | 7.62 | 3 | 80S | 15.51 |

| 88.90 | 11.132) | 3 | 160 | 21.67 |

| 101.60 | 3.05 | 3½ | 10S | 7.53 |

| 101.60 | 5.74 | 3½ | 40S | 13.78 |

| 101.60 | 8.08 | 3½ | 80S | 18.92 |

| 114.30 | 3.05 | 4 | 10S | 8.50 |

| 114.30 | 6.02 | 4 | 40S | 16.32 |

| 114.30 | 8.56 | 4 | 80S | 22.67 |

| 114.30 | 13.492) | 4 | 160 | 34.05 |

| 141.30 | 6.55 | 5 | 40S | 22.10 |

| 141.30 | 9.53 | 5 | 80S | 31.44 |

| 141.30 | 15.882) | 5 | 160 | 49.87 |

| 168.28 | 3.4 | 6 | 10S | 14.04 |

| 168.28 | 7.11 | 6 | 40S | 28.69 |

| 168.28 | 10.97 | 6 | 80S | 43.21 |

| 168.28 | 14.27 | 6 | 120 | 54.75 |

| 168.28 | 18.262) | 6 | 160 | 68.59 |

| 219.08 | 8.18 | 8 | 40S | 43.20 |

| 219.08 | 12.7 | 8 | 80S | 65.63 |

| 219.08 | 18.23 | 8 | 120 | 91.30 |

| 219.08 | 23.012) | 8 | 160 | 112.97 |

Check updated Price of API 5L Carbon Steel material and API 5L Seamless Tube Size

API 5L LSAW Pipes Prices

| API 5L Pipe Price List | Carbon Steel API 5L ERW Pipes Per Unit |

|---|---|

| API 5L Carbon steel line seamless pipes price | $550.00-$600.00/ Ton |

| CS 5L Gr B black seamless steel pipes | $599.00-$639.00/ Ton |

| api 5l seamless line pipes price | $800.00-$895.00/ Ton |

| pipelines Carbon Steel 5ct l80 seamless steel pipes | $600.00-$1,000.00/ Metric Ton |

Api 5l Pipe Vs Astm A106 Gr.b

API 5L Pipes come from API 5L Specification for Line Pipe with the application of water, gas and oil Industries. 5l Grade Steel Pipe has grade designation A and B. API 5L Grade b pipe can be two of API 5L product service level (PSL),that’s is API 5L PSL1 Pipe and API 5L PSL2 Pipes

ASTM A106(S/A 106) pipe is the standard specification for carbon steel seamless pipe for high-temperature and pressures service. ASTM A106 pipe contains three grades like ASTM A106 Grade A, ASTM A106 Grade B, ASTM A106 Grade C. ASTM A106 grade B Pipe is used in boilers, power plants, petrochemical plants and ships.

Chemical Requirement

| Standards | C max % | Mn max% | S max % | Si min % | Cr max % | Cu max % |

| A106 Gr.B | 0.30 | 0.29-1.06 | 0.035 | 0.10 | 0.40 | 0.40 |

| API 5L Gr.B/L245 | 0.28 | 1.20 | 0.030 | / | 0.50 | 0.50 |

Tensile Requirement

| Standards | Tensile Strength Mpa | Yield Strength Mpa | Elongation % |

| A106 Gr.B | ≥415 | ≥240 | 20 |

| API 5L Gr.B/L245 | ≥415 | ≥245 | 23 |

Equivalent standards

| Standard | SWAMLESS | WELDED | Other standards |

| API 5L Line Pipe B/L245 | EN 10216-1 P265 | EN 10217-1 P265 | BS 3601 430 |

| A106 Gr.B | EN 10216-2 P265GH | / | BS 3601 430 |