Held Wide Water and Gas Shut Off Valve Stock At Best Price

We are Largest Fuel, Electric Hydraulic and Stainless Steel Shut Off Valve Suppliers

Shut off Valves

2 Way Hydraulic Shut Off Valve

3 Way Shut Off Valve

Stainless Steel Shut Off Valve

Table of Content

- Specification of Shut off Valves

- Water Shut Off Valve Size Chart

- Gas Shut Off Valve Types

- Fuel Shut Off Valve Material

- Price List of 2 Way Hydraulic Shut Off Valve

- 3 Way Shut Off Valve Application

- Difference Between Shut Off Valve And Ball Valve

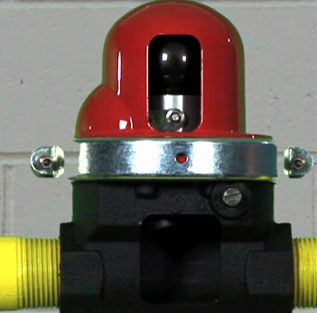

- Advantages of Electric Hydraulic Shut Off Valve

- Stainless Steel Shut Off Valve Dimension Chart

- Manual Heater Shut Off Valve Features

Specification of Shut off Valves

| Manufactured sizes | NPS 1/4" thru NPS 60". Higher or special sizes may be developed upon request, please enquiry |

|---|---|

| Pressure ratings | ANSI 150#, ANSI 300#, ANSI 600#. ANSI 900#, ANSI 1500#, ANSI 2500#, ANSI 4500#. Please enquiry for higher or lower ratings |

| Valve connections | ASME B16.5 (FF, RF, RTJ, Threaded), ASME B16.47 Series A or B, MSS SP-44, ASME B16.25 (BW, SW, WE). Please enquiry for special connections |

| Standardization | API 6D / ISO 14313, ASME B16.34, BS 5351, API 608, BS EN ISO 17292, API 6FA, BS 6755 Part 2, ASME B16.10, API 598, GOST, JIS, NACE 01-MR-0175. Please enquiry for other standards |

Check Manual Heater and Pneumatic Shut Off Valve Sizes

Water Shut Off Valve Size Chart

DIN 11850 DN 25 - DN 100

ASME BPE OD 1" - OD 4"

Gas Shut Off Valve Types

Electric Water Shut Off Valve

Hot Water Drinker Water Shut Off Float Valve

12v 24v Dn25 Dn32 Electric Shut Off Valve

2 Inch Shut Off Float Valve For Quick Flow

Fuel Tank Truck 4" Pneumatic Bottom Electric Fuel Shut Off Valve

2 Inch Shut Off 12volt Water Brass Solenoid Valves

4v210-08 1/4 Inch Electric Air Shut Off Valve

Dc8v-dc16v Automatic Manipulator Shut Off Valve For Alarm Shutoff Gas Water Pipeline

Fuel Shut Off Valve Material

| Body | ASTM A216, A105, A350, A182, A351, A352, A890, A995, C95300, C95800, MONEL, INCONEL. Please enquiry for different material configurations |

|---|---|

| Trim | ASTM A216, A105, A350, A182, A351, A352, A890, A995, C95300, C95800, MONEL, INCONEL. Please enquiry for different material configurations |

| Seat(s) | PTFE, NYLON, PEEK, NBR, KELF, ENP (Electroless nickel plating), HC (Hard chrome), TC (Tungsted carbide). Please enquiry for different material configurations |

| Sealing | BUNA-N, EPDM, VITON, Flexible graphite, FKM, HNBR, Nitrile, Neoprene. Please enquiry for different material configurations |

Price List of 2 Way Hydraulic Shut Off Valve

| Shut Off Valve Price List | Gas Shut off Valve Price Per piece |

| automatic water shut off valve 22mm/28mm Water Bypass Valve | US $0.80-$9.00 / Piece |

| 1 1/2" DN40 SVA Straight shut-off valve | US $150.00 / Set |

| 3/8 plastic barbed shut off valve 3/4 | US $0.19-$0.25 / Piece |

| nozzle hydraulic shut off pvc brass ball valve | US $7.00-$70.00 / Piece |

3 Way Shut Off Valve Application

- Silos/cement

- Pigment & granulate handling

- Ceramics/glass/plastics industries

- Waste water treatment

- Pharmaceuticals and foodstuffs

- Wine making

- Metering & weighing systems

- Powder coating

- Vacuum toilet systems

- Vacuum and compressed air control units

Difference Between Shut Off Valve And Ball Valve

Shutoff Valves |

Ball Valves |

|

| It also know as lock out valve, cut off valve, and shutdown valve | ball valves are categorized as low pressure and high pressure ball valves. | |

| Advantages |

|

|

| Types |

|

|

| Price | More Expensive | Less Expensive |

| Uses | designed to safely manage compressed air in pneumatic applications | It is used to control flow, pressure control in gas distribution systems |

Advantages of Electric Hydraulic Shut Off Valve

- Low cost

- Smaller size

- Lighter weight

- Precise and accurate

- No blockages or damage

Find Here On Off Valve Dimensions, Check Emergency Water Shut Off Valves Specification And Equivalent

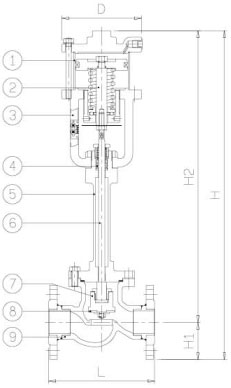

Stainless Steel Shut Off Valve Dimension Chart

| Valve | L | H1 | ATC | ATO | D | |||

| mm | inch | H2 | H | H2 | H | |||

| 15 | 1/2" | 150 | 48 | 442 | 490 | 538 | 586 | 120 |

| 20 | 3/4" | 150 | 50 | 442 | 492 | 538 | 588 | 120 |

| 25 | 1" | 160 | 63 | 452 | 515 | 548 | 611 | 120 |

| 40 | 1-1/2" | 200 | 70 | 548 | 618 | 644 | 714 | 150 |

| 50 | 2" | 230 | 78 | 561 | 639 | 657 | 735 | 150 |

Importers Of Safety and Earthquake and Check Applications & Features of Toilet Shut Off Valve

Manual Heater Shut Off Valve Features

- Fail-safe versions available

- Visual position indication

- Limit Stop available

- Million cycle life

- Can be operated pneumatically or hydraulically

- Uses PTFE parts for inherent lubricity