Suppliers of Fully Lined and Stainless Steel Plug Valve

View Size Chart of 2/ 3 Way and Eccentric Plug Valve

Plug Valves

Sleeved Plug Valve

Fully Lined Plug Valve

Table of Content

- specification chart of Sleeved Plug Valve

- Most famous types of Fully Lined Plug Valve

- Non Lubricated Plug Valve Sizes In Mm

- Standards of Lubricated Plug Valve

- Materials of Multiport Plug Valve

- 2 Way Plug Valve Features

- Dimension Chart of Eccentric Plug Valve

- Prices of 3 Way Plug Valve

- Difference Between Plug Valve And Ball Valve

Specification Chart of Sleeved Plug Valve

| Size Range | 65mm - 600mm (2.1/2” - 24”) larger diameters on request |

| Flange Accomodation | BS4504 PN16/25 ANSI B 16.5, Class 125/250 DIN 2501 PN16/25 |

| Temperature Range | -10°C to +200°C (depending on material & pressure) |

| Pressure Rating | Maximum : 27 Bar (depending on Flange Drilling & size) |

| Body Material | Cast Iron BS1452 Gr.220 (Epoxy Coated) Ductile Iron BS2789 Gr.500/7 (Epoxy Coated) Carbon Steel ASTM A216 WCB Aluminium Bronze BS1400 AB2 Stainless Steel ASTM A351 CF8M |

| Plug Material | Ductile Iron BS2789 Gr.500/7 Stainless Steel ASTM A351 CF8M |

| Plug Coating Material | EPDM Nitrile Fluoroelastomer (Viton) Neoprene Natural Rubber Butyl Hypalon |

| Seat Material | Epoxy Neoprene Natural Rubber Welded Nickel Stainless Steel |

| Options | Full Elastomer Body Lining |

Most famous types of Fully Lined Plug Valve

2 and 3 Way Plug Valves Class 150, 300, 600LB

Ballcentric Plug Valves

Non-Lubricated Sleeved Plug Valves, Class 150, 300, 600, 900 LB

Eccentric Plug Valves, EPV, Class 150, 300, 600, 900 LBLB

RTJ Plug Valves, Three Way, API 6D, 600 LB

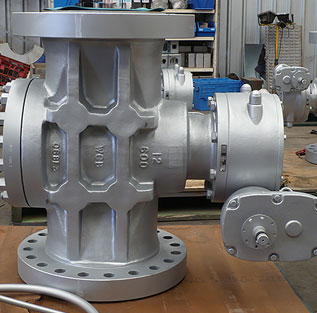

ASTM A351 CF8M Plug Valves, Size DN 250, Class Rating PN 16, Flanged Ends, Gear Operator.

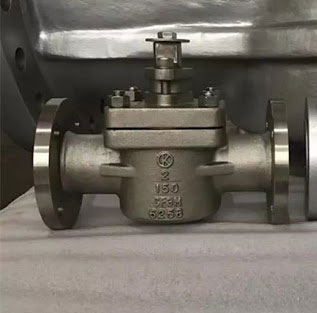

A105 Plug Valves, API 599, API 6D, 1 Inch, Class 150, SW End

API 6D Plug Valves, A105, 1.5 Inch, Class 600, SW End, Wrench

Lubricated Plug Valves, API 599, 32 Inch, 600LB

Three Way Jacket Plug Valves, WCB, 4 X 3 Inch

Sleeve Plug Valves, API 599, WCB, 8 Inch

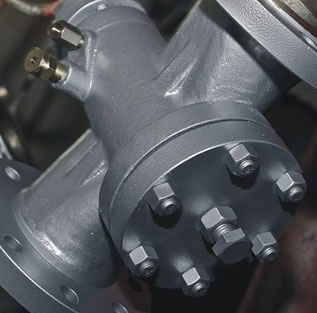

RF Plug Valves, Inverted Type, WCB, CL900

Non Lubricated Plug Valve Sizes In Mm

| To suit pipework NB | Face - Face A | CL to end of wrench | CL to top of wrench | |

| Inches | mm | mm | mm | mm |

| 1/2" | 15 | 108 | 152 | 121 |

| 3/4" | 20 | 117 | 152 | 121 |

| 1" | 25 | 127 | 178 | 122 |

| 1.1/2" | 40 | 165 | 229 | 140 |

| 2" | 50 | 178 | 305 | 160 |

| 3" | 80 | 203 | 457 | 190 |

| 4" | 100 | 229 | 762 | 229 |

| 6" | 150 | 267 | G/O | G/O |

Standards of Lubricated Plug Valve

- Plug-Valves with flanges

- DN 15 - 600 / PN 10 - 40

- NPS ½" - 24" / class 150 - 300

- Free of cavity

- Maintenance free - self lubricating

- Mounting-flange for actuators acc. to DIN ISO 5211

- Easy accessible adjustment of the plug, even with an actuator mounted

- TA-Luft 2002 approval

- PED 97/23/EG

- Fire safe design API 607 / ISO 10497

- FDA Conformity

Are you looking for Multiport, Ductile Iron, Check Ballcentric Plug Valve Material

Materials of Multiport Plug Valve

| Item # | Part Description | Stainless Steel | Brass |

| 1 | Body | ASTM A 479Type 316 | ASTM B 16Alloy C36000 |

| 2 | Plug* | ASTM A 479Type 316 | ASTM B 16Alloy C36000 |

| 3 | Seat** | Fluorocarbon Rubber | |

| 4 | O-Ring Seals** | Fluorocarbon Rubber | |

| 5 | Back-up Rings | PTFE | |

| 6 | Handle | Nylon 6/6 | |

| 7 | Handle Pin | 316 Stainless Steel | |

| 8 | Body Pin | 316 Stainless Steel (not shown) | |

| 9 | Retaining Ring | 316 Stainless Steel | |

2 Way Plug Valve Features

- Heavy-duty, robust construction, maintenance-free

- Bubble-tight shut-off throughout the full pressure and temperature range

- Cavity-free design, max. permeation protection

- Zero stem leakage provided by an innovative stem sealing mechanism

- Maximum flow rates at lowest pressure drops

- Easy replacement of components on site

- Flanges acc. to DIN PN10/16 resp. ANSI 150lbs for installation into existing piping systems

- Size range DN15 to DN100

Check Dimension of Electric, Hydraulic and Pneumatic Actuated Plug Valve

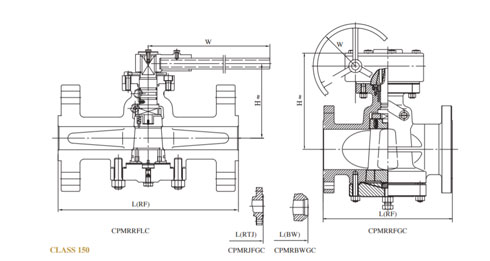

Dimension Chart of Eccentric Plug Valve

CLASS 150

| NPS | in | 2 | 2-1/2 | 3 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | 26 | 28 | 30 | 32 | 36 |

| DN | mm | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 650 | 700 | 750 | 800 | 900 |

| L(RF) | mm | 178 | 191 | 203 | 229 | 267 | 292 | 533 | 610 | 686 | 762 | 864 | 914 | 1067 | 1245 | 1346 | 1397 | 1524 | 1727 |

| L(BW) | mm | 267 | 305 | 330 | 356 | 457 | 521 | 559 | 635 | 686 | 762 | 864 | 914 | 1067 | 1245 | 1346 | 1397 | 1524 | 1727 |

| L(RTJ) | mm | 191 | 203 | 216 | 241 | 279 | 305 | 546 | 622 | 699 | 775 | 876 | 927 | 1080 | 1270 | 1372 | 1422 | 1553 | 1756 |

| H | mm | 140 | 168 | 190 | 220 | 278 | 300 | 320 | 380 | 415 | 460 | 500 | 580 | 650 | - | - | - | - | - |

| W | mm | 400 | 450 | 550 | 200 | 200 | 350 | 350 | 350 | 350 | 350 | 350 | 600 | 800 | - | - | - | - | - |

| WT(RF) | Kg | 18 | 24 | 33 | 54 | 90 | 150 | 210 | 275 | 372 | 520 | 786 | 1006 | 1708 | - | - | - | - | - |

CLASS 300

| NPS | in | 2 | 2-1/2 | 3 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | 26 | 28 | 30 | 32 | 36 |

| DN | mm | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 650 | 700 | 750 | 800 | 900 |

| L(RF) | mm | 216 | 241 | 283 | 305 | 403 | 419 | 457 | 502 | 762 | 838 | 914 | 991 | 1143 | 1245 | 1346 | 1397 | 1524 | 1727 |

| L(BW) | mm | 267 | 305 | 330 | 356 | 457 | 521 | 559 | 635 | 762 | 838 | 914 | 991 | 1143 | 1245 | 1346 | 1397 | 1524 | 1727 |

| L(RTJ) | mm | 232 | 257 | 298 | 321 | 419 | 435 | 473 | 518 | 778 | 854 | 930 | 1010 | 1165 | 1270 | 1372 | 1422 | 1553 | 1756 |

| H | mm | 210 | 228 | 240 | 270 | 285 | 315 | 355 | 380 | 420 | 460 | 540 | 585 | 650 | - | - | - | - | - |

| W | mm | 470 | 550 | 620 | 300 | 350 | 350 | 350 | 350 | 350 | 350 | 600 | 600 | 800 | - | - | - | - | - |

| WT(RF) | Kg | 20 | 27 | 36 | 58 | 120 | 195 | 275 | 355 | 514 | 670 | 920 | 1253 | 2088 | - | - | - | - | - |

Ready Stock of double block and bleed, natural gas plug valve. Check full port cock valve Price List

Prices of 3 Way Plug Valve

| Plug Valve Price list | Lubricated Plug Valves Per Unit (UAE) |

|---|---|

| SS Quarter-turn Instrument Plug Valve, 1/4 In. Tube Fitting 1.6 Cv. Black Handle SS-4p4t-bK | 181.77 |

| Stainless Steel Valves -SS Quarter Turn Plug Valve-(SS-4p4t4) | 110.00 |

| Stainless Steel Valves - SS Quarter Turn Plug Valve-(SS-8p6t4) | 203.20 |

| SS-4p4t4 Stainless Steel Valves - Quarter Turn Plug Valve- (Banga-0.0000) | 110.00 |

| Stainless Steel Valves - SS Quarter Turn Plug Valve (SS-8p6t4) | 203.20 |

Difference Between Plug Valve And Ball Valve

| Characteristics | Plug Valve | Ball Valve |

| Shape | Plug valves are valves with conically-tapered or cylindrical ‘plugs’. These can be rotated inside the valve body to control flow through the valve. | Ball valves are a type of control valve with a spherical disc, which controls the flow through it |

| Flow | better control flow | less Control flow |

| Port | full port or reduced port | mostly full port |

| Size | large | small |

Plug Valves Stocking Distributor Of Following Manufacturers in UAE

Stockist Of Lubricated Plug Valves in UAE

Stock Of Non-lubricated Plug Valves in Dubai

Stockist Of Multiport Plug Valves in Dubai

Supplier Of Sleeved Plug Valves in Dubai

Eccentric Plug Valves Supplier in Dubai

Ptfe Lined Plug Valves Stock in UAE

Stock Of Expanding Plug Valve in Dubai

Lift-type Plug Valves Stockist in UAE

Stockholder Of Elastomer Sleeved Plug Valve in UAE

Fully Lined Plug Valve Stockholder in UAE

Supplier Of Manually Operated Plug Valves in UAE

Two Way Plug Valves Stockist in Dubai

3-way Plug Valve Stock in UAE

Stockholder Of 4 Way Plug Valve in Dubai

Double Block And Bleed Plug Valve Stockholder in Dubai

Stainless Steel Plug Valve Stocking Distributor in UAE

Stocking Distributor Plug Valve Hydraulic Actuator in UAE

Stock Of Plug Valve Electric Actuator in UAE

Plug Valve Material Supplier in UAE

Stock Of Lubricated Jacketed Plug Valve in UAE

Cast Iron Thread Plug Valve Stock in Dubai

2 Way Flanged Sleeved Plug Valves Stocking Distributor in Dubai

Stocking Distributor Of Cast Steel Plug Valve in Dubai